Determination of Precise Lattice Parameter of FCC and BCC phases using X-ray diffraction

Errors in measurement of interplanar spacing d and lattice parameter(s) a using modern diffractometers can occur due to :

- Misalignment of the instrument

- Absorption of X-Rays by the specimen

- Displacement of the specimen from the diffractometer axis must be minimized (observational error)

- Vertical divergence of the incident beam

- Use of a flat specimen instead of a curved one to correspond to the diffractometer circle

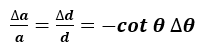

Figure 1: X-Ray Diffractogram for an FCC material

Observational error :

- For a cubic material :

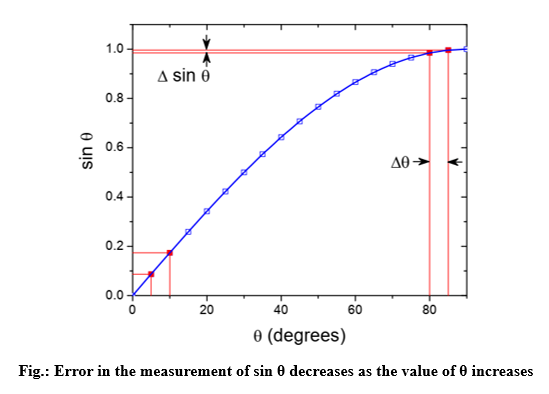

Where the d-spacing is measured from Bragg’s law :

Here, n = 1 which is the first order of diffraction and λ = 1.5406 Å for Cu-Kα radiation.

- Precision in measurement of a or d depends on precision in derivation of sinθ.

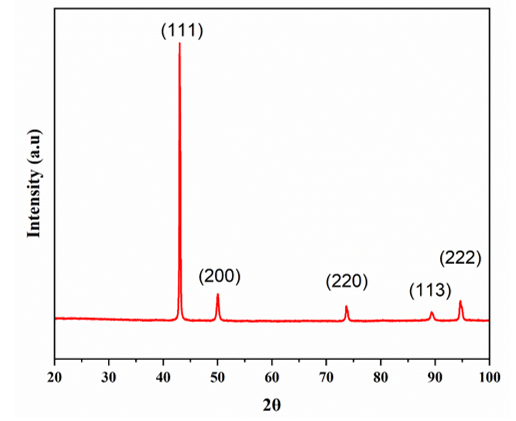

Figure 2: Error in the measurement of sin θ decreases as the value of θ increases

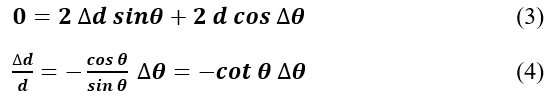

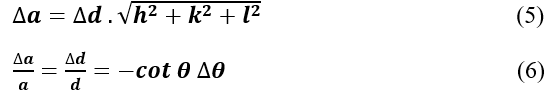

Take partial derivative of the Bragg equation :

For a cubic system :

The term ∆a⁄a (or ∆d⁄d) is the fractional error in a (or d) caused by a given error in θ. The fractional error approaches zero as θ approaches 90°.

Values of a will approach the true value as we approach 2θ = 180° (i.e., θ = 90°). We can’t measure a value at 2θ = 180°. We must plot measured values and extrapolate to 2θ = 180° versus some function of θ.

Absorption Error :

- For a cubic crystal with a lattice parameter a, a Nelson-Riley extrapolation function is used :