Design and develop a P & ID for Pressure and Vacuum sensors calibration set-up

Introduction

The measurement of pressure and vacuum plays an extensive and important role in the modern world. The industrial revolution was largely powered by the pressure generated by transforming water into steam, and the need to measure pressure, over wider ranges and with increasing accuracy, has expanded ever since. Applications are found in industries as diverse as nuclear, power, gas, petrochemical, biological, pharmaceutical, meteorological, automotive, environmental, semi-conductor, optical, aerospace, defence, ventilation, filtration and process control in general. The validity of the measurements is essential for trade, efficiency, quality and safety.

Pressure and Vacuum Plant design purpose to identify the variation in static and dynamic characteristics. We have different device communication protocols, manufacturers, accuracy and response time. It will be helpful for future research and selection of an accurate sensor for a particular application area. Here we are doing experiments with 9 pressure transmitters and 5 vacuum transmitters which has different properties.

A PLC (Programmable Logic Controller) is an industrial digital computer designed to control manufacturing processes or machinery in real-time. It is rugged, reliable, and used in automation systems to replace hard-wired relay logic.

Programming Languages for PLC : Ladder Logic, Function Block Diagram (FBD), Structured Text, Instruction List, and Sequential Function Chart (SFC).

Input/Output (I/O) for PLC : PLCs receive inputs from sensors, switches, or devices and send outputs to actuators, motors, valves, etc.

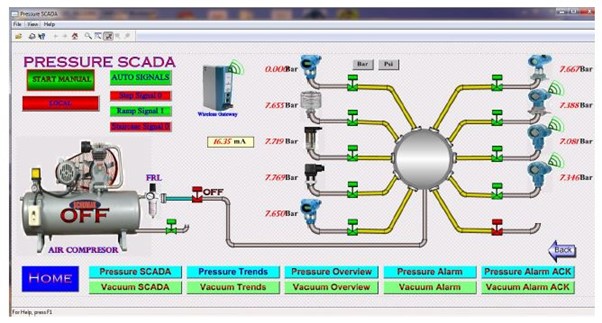

SCADA stands for Supervisory Control and Data Acquisition. It is a software-based system used for monitoring, controlling, and analyzing industrial processes from a centralized location.

While PLCs control machines locally, SCADA provides a supervisory layer to visualize, monitor, and sometimes control multiple PLCs and remote equipment.

Pressure & vacuum Pilot Plant Insight

The Pressure vacuum Pilot Plant hardware contain the combined setup, but it is operated individually. Both plant has same PLC. Pressure setup has 0 to 10 bar three phase compressor and 9 different properties pressure transmitters (PT1 to PT9 and reference slandered is PT3). Vacuum setup has three phase 0 to -1000 mbar vacuum pump. It has 5 different properties vacuum transmitters VT1 to VT5 and reference standard is VT3.

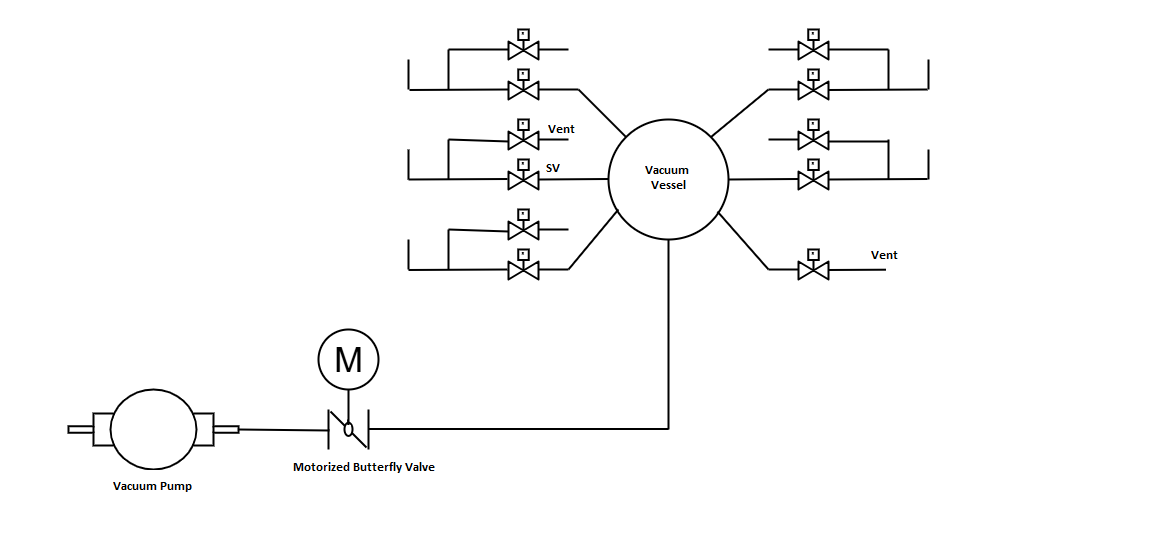

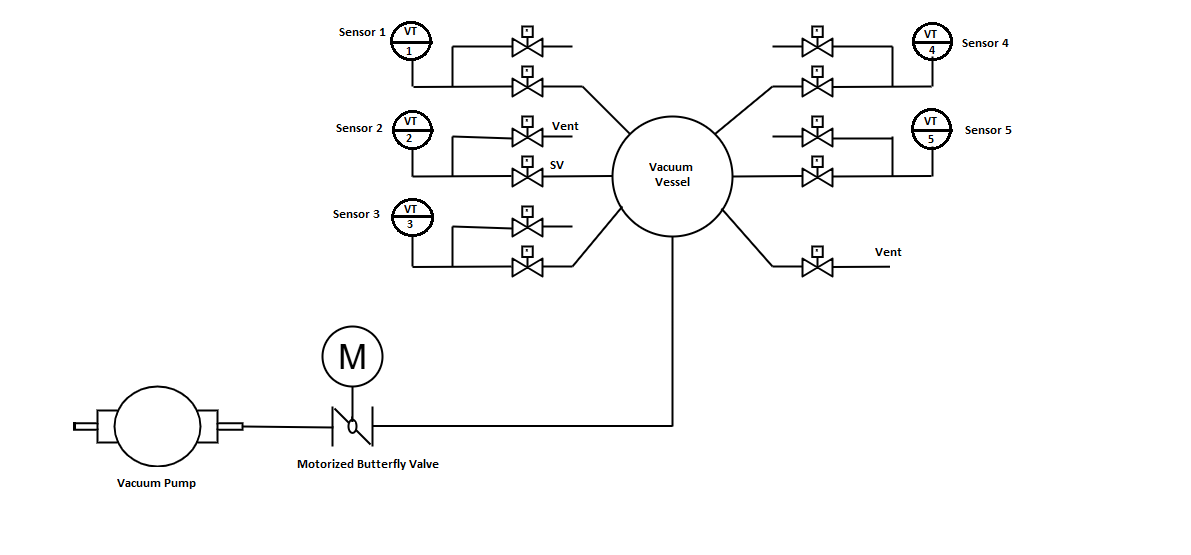

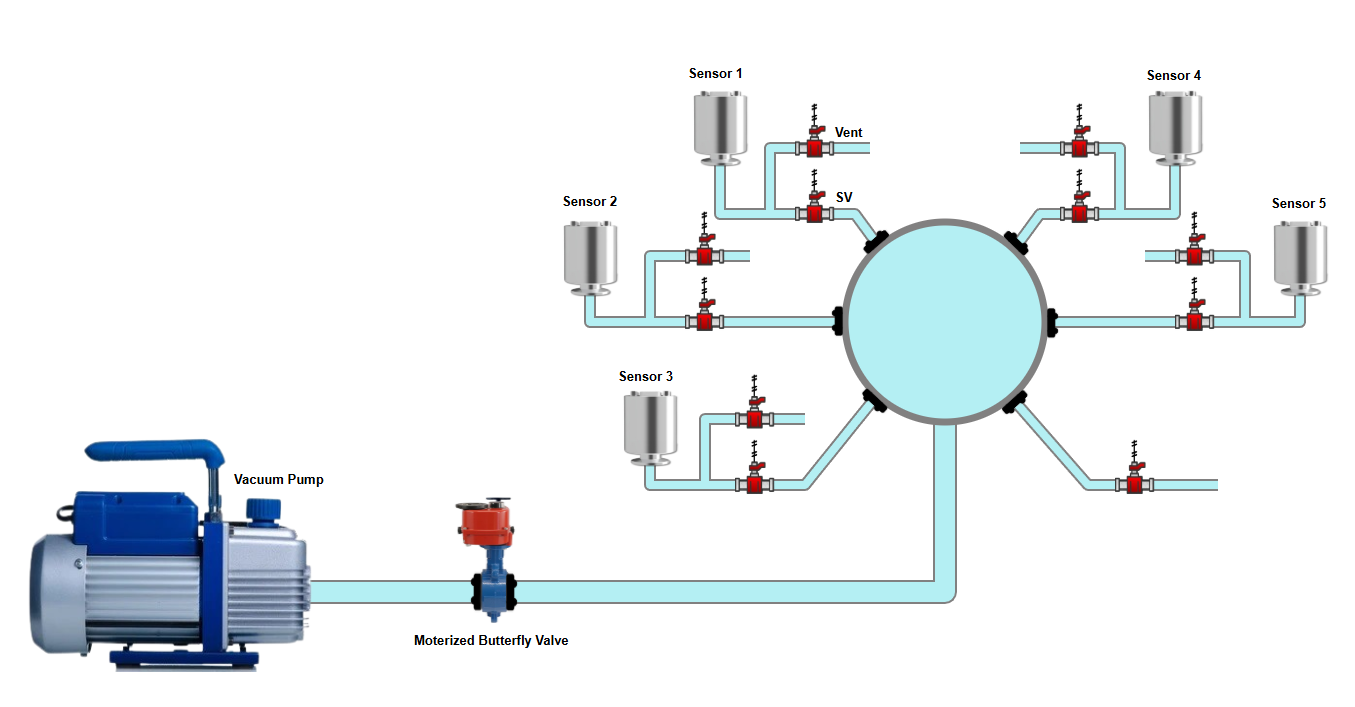

Piping Diagram of Vacuum System

Pressure Vaccum Plant Setup

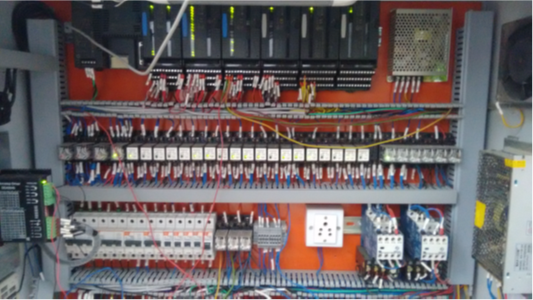

Pressure and Vacuum plant control panel setup

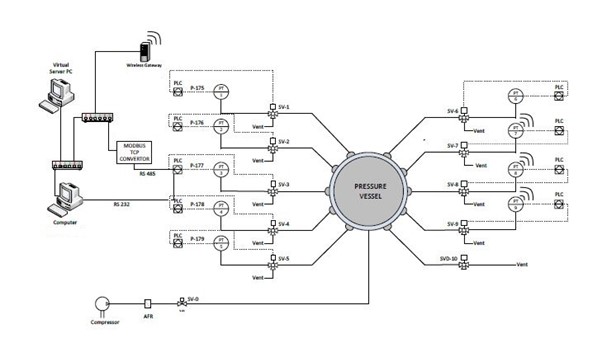

Pressure plant description

Pressure setup has different manufacturer and device communication protocols transmitters.

- Foundation fieldbus pressure transmitter 1 (PT1)

- ABB HART pressure transmitter 2 (PT2)

- Forbs marshal pressure transmitter 3 (PT3)

- Baumar pressure transmitter 4 (PT4)

- Rosemount HART pressure transmitter 5 (PT5)

- Rosemount HART pressure transmitter 6 (PT6)

- Rosemount wireless HART pressure transmitter 7 (PT7)

- Rosemount wireless HART pressure transmitter 8 (PT8)

- Rosemount wireless HART pressure transmitter 9 (PT9)

- Smart Wireless Gateway

- GE Versa Max PLC

- Ethernet switches

- Engineering station

- Modbus RTU to TCP=IP converter

- 0 to 10 bar three phase air compressor

- 9 3/2 solenoid valve (SV1 to SV9)

- 1 3/2 Air pressure isolation solenoid valve 0 (AP - ISV0)

- Air vessel drain solenoid valve 10 (AV - DSV10)

- Compressor unloading solenoid valve 11 (COMP - USV11)

Pressure plant communication and piping & Instrument Diagram

Pressure plant operator SCADA

Vacuum plant description

Vacuum setup has different manufacturer and device communication protocols transmitters.

- Baumar vacuum transmitter 1(VT1)

- ABB HART vacuum transmitter 2 (VT2)

- Forbs marshal vacuum transmitter 3 (VT3)

- Rosemount wireless HART vacuum transmitter 4 (VT4)

- Rosemount HART vacuum transmitter 5 (VT5)

- Smart Wireless Gateway

- GE VersaMax PLC

- Ethernet switches

- Engineering station

- Modbus RTU to TCP=IP converter

- 0 to -1000 bar three phase air compressor

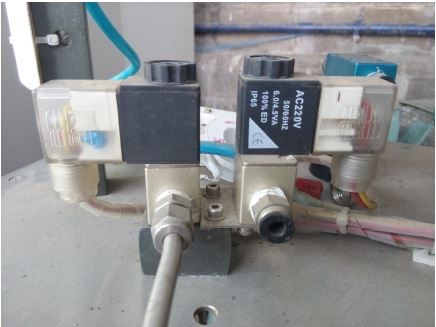

- 5 2/2 solenoid valve (SV1 to SV5)

- 5 2/2 Vacuum drain solenoid valve (VDSV1 to VDSV5)

- 1 2/2 Vacuum vessel drain solenoid valve (VVDSV6)

- Butterfly valve

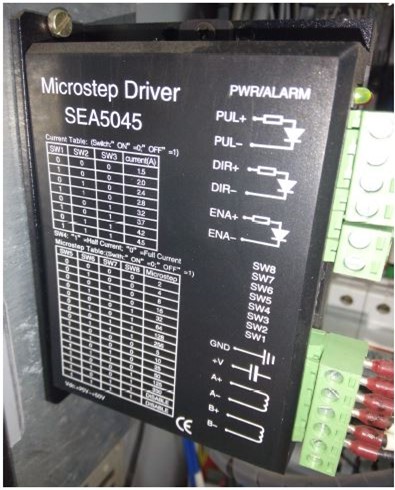

- Stepper motor

Vacuum plant communication and piping & Instrument Diagram

Vacuum Mimic Diagram

Pressure and Vacuum plant Components

Air Compressor

Smart Wireless Gateway

Solenoid Valve 2v2

Stepper Motor Drive

Stepper Motor operated butterfly valve

Vacuum Pump