Performance Characteristics of Kaplan Turbine

Experimental Setup

The test rig consists of a 1 KW Kaplan turbine supplied with water from a suitable 5HP pump through pipelines, a valve and flow measuring venturi meter. The turbine consists of a cast iron body with a volute casing, an axial flow gunmetal runner, a ring of adjustable guide vanes and a draft tube. The hand wheel consists of three airfoil section. A rope brake drum is mounted on turbine to absorb the power developed. Suitable dead weight and a hanger arrangement, a spring balance and cooling water arrangement is provided for brake drum.

The flow through the pipelines into the turbine is measured with venturi meter fitted in the pipeline. two pressure gauges are provided to measure the pressure difference across venturi meter. The net pressure difference across the turbine inlet and exit is measured with pressure gauge and a vacuum gauge. The turbine output is determined with the rope brake drum. A tachometer is used to measure the speed. Power developed by the Kaplan turbine will be Measured.

Formulae

- Input Power (Pi) = ρ x g x Q x h kW

- Discharge (Q) = Cd = k ×√h LPM

k = 84.5 is a constant depends on venturi meter dimensions - H = h1 – h2(s1/s2-1)

H = Suction head (Hs) + Delivery head (Hd) + Datum head

H = Head (of water) acting on Kaplan Turbine

- Output Power PO = T1-T2×g×dia.of brake drum

- T = ( T1 – T2) x g x dia. of brake drum

- Ƞ = Po/Pi x 100

Procedure –

- Add minimum load to the weight hanger of brake drum say 1 kg

- Close the main gate valve and start the pump

- Open the gate valve while monitoring the inlet pressure to the turbine and set it for the design value of 1 Kg/cm2

- Open the cooling water valve for cooling the brake drum

- Measure the turbine RPM with the tachometer

- Note the pressure gauge and vacuum gauge reading at turbine inlet and outlet

- Note the venturi meter pressure gauge reading P1 and P2

- Add additional weights and represent the experiment for both loads

- For constant speed test , the main valve has to be adjusted to reduce or increase the inlet head to turbine for varying loads

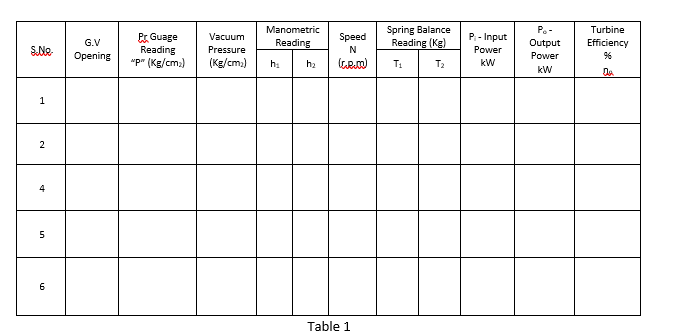

Observations

- Mean Diameter of the brake drum, D(Dd + Dr) = 200 mm

Where Dd = diameter of the drum, Dr = diameter of rope - d1 = Dia. of Venturi Inlet = 100 mm, d2 = Dia. of venturi throat = 59.16 mm

- Speed (RPM) =

- Q=k √h k = 84.5

Graphs

Plot the following curves and determine the efficiency of the Kaplan turbine

- Speed vs. Efficiency

- Speed vs. Power Input

- Speed vs. Power Output