Strain Ageing and Yield Point Phenomenon in Mild Steel

Brief Description of the Equipment/Machine

A tensile testing machine is required to obtain tensile properties of Mild Steels.

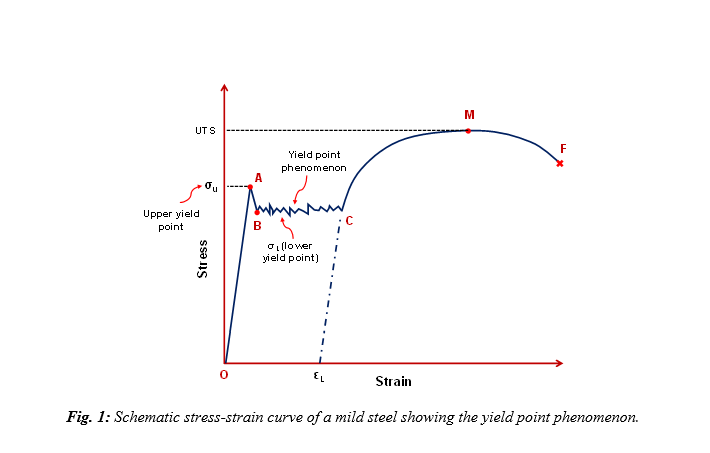

Yield point phenomenon

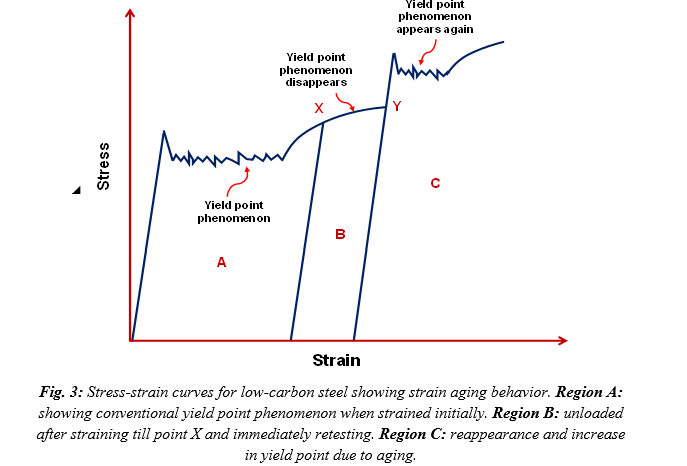

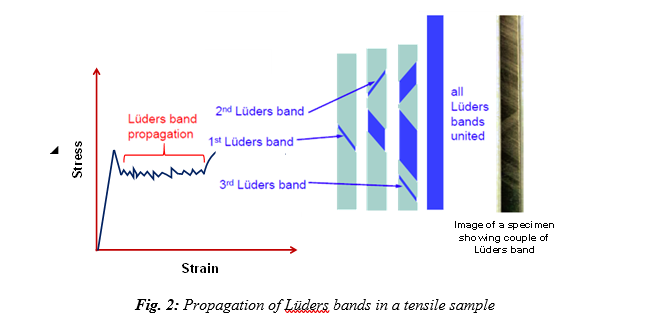

Some steels and other materials exhibit the tensile stress-strain behavior as shown in Fig. 1. The elastic-plastic transition is very well defined and occurs abruptly in what is termed a yield point phenomenon. The normal elastic extension (region OA) is terminated at a stress level known as the upper yield point (σu). Plastic deformation is initiated at Point ‘A’ with an actual decrease in stress. Continued deformation fluctuates slightly about some constant stress value (region BC), termed the lower yield point (σL). Deformation at this stage is not homogeneous. In a portion of the tensile sample where there is a stress concentration, a deformation band appears, called Lüder bands (or stretcher strains), as shown in Fig. 2. The upper yield point may be regarded as a nucleation stress, and the lower yield point as the growth of the Lüders bands themselves. Thus, at the lower yield stress, deformation proceeds by the growth of Lüders bands, which spread along the specimen, until at the point ‘C’ the entire surface of the test specimen is covered. In the plateau region of the stress-strain curve, there could be two or more Lüders bands. Beyond this point, from C to the ultimate tensile stress at M, deformation is essentially homogeneous and thereafter necking develops, leading to normal ductile fracture at F.

Mechanism

The yield point effect is explained by the affinity of interstitially dissolved atoms (C and N) for dislocations. These solute atoms segregate to the core of dislocations and pin them (don’t allow dislocations to move). Now, for slip to occur, the applied stress must be great enough (related to upper yield point) to pull some dislocations away from the interstitial atoms that pin them. Once a dislocation breaks free from interstitials, it can move at a lower stress (related to lower yield stress).

Strain aging

Strain aging is a behavior associated with the yield-point-phenomenon in which the strength of the metal is increased and the ductility is decreased on heating at a relatively low temperature after cold-working. Fig. 3 shows the effect of strain aging on the flow curve for a low-carbon steel.

The low-carbon steel shows the conventional yield point phenomenon (as discussed above) when load is applied (region A). Straining the specimen to point X, then unloading and retesting without appreciable delay or any heat treatment does not show any yield point phenomenon (region B) since dislocations have been torn away from the atmosphere of carbon and nitrogen atoms and there is not sufficient driving force (time/temperature) for them to pin again. If now the specimen is strained to point Y and unloaded, and then again reloaded after aging for several days at room temperature or several hours at an aging temperature, the yield point will reappear, and it will now be higher than the initial yield point (region C). Moreover, the yield point will be increased by the aging treatment from Y to Z. The reappearance of the yield point is due to the diffusion of carbon and nitrogen atoms to the core of dislocations during the aging period to form new atmospheres of interstitials anchoring the dislocations.