To study and prepare Process Flow Diagram

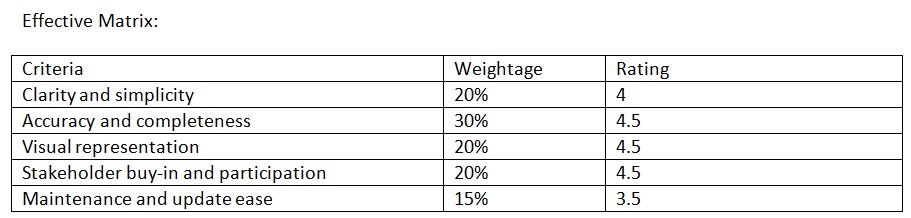

Preparing process flow diagram is an expert’s job and has to be done very carefully. Here is a detailed process, its pros and cons, effective matrix, and teams involved while preparing a process flow diagram for a process automation project :

Sample assignment Process :

Preparing a Process Flow Diagram for a Process Automation Project

Step 1: Define the Process Boundaries

- Identify the specific process to be automated

- Determine the start and end points of the process

- Define the inputs and outputs of the process

Step 2: Gather Information and Data

- Conduct stakeholder interviews to gather information about the process

- Review existing process documentation and data

- Observe the process in action to identify key steps and activities

Step 3: Identify Process Steps and Activities

- Break down the process into individual steps and activities

- Identify the tasks, decisions, and actions involved in each step

- Determine the sequence of steps and activities

Step 4: Create the Process Flow Diagram

- Use a process mapping tool or software to create the diagram

- Represent each step and activity with a symbol or shape

- Use arrows to show the flow of the process

- Include decision points, loops, and branches as necessary

Step 5: Review and Refine the Diagram

- Review the diagram with stakeholders to ensure accuracy and completeness

- Refine the diagram based on feedback and suggestions

- Ensure the diagram is clear, concise, and easy to understand

Step 6: Finalize the Diagram and Document the Process

- Finalize the process flow diagram and document the process

- Include annotations and notes to explain each step and activity

- Store the diagram and documentation in a shared repository for future reference

Pros:

- Helps to clarify and understand the process

- Identifies inefficiencies and areas for improvement

- Facilitates communication among team members and stakeholders

- Provides a visual representation of the process

- Enables process automation and optimization

Cons:

- Can be time-consuming and resource-intensive

- Requires stakeholder buy-in and participation

- May not capture all nuances and complexities of the process

- Can be difficult to maintain and update

To make process flow diagram flawless the explicit list of care to be taken while preparing a Process Flow Diagram (PFD) for a process automation project is as follws :

I. Understanding the Process

- Familiarize yourself with the process: Before creating a PFD, ensure you have a thorough understanding of the process, including its inputs, outputs, and all the steps involved.

- Gather information from various sources : Collect data from operators, maintenance personnel, engineers, and other stakeholders to ensure accuracy and completeness.

- Review existing documentation: Study existing process descriptions, flowcharts, and P&IDs (Piping and Instrumentation Diagrams) to gain a deeper understanding of the process.

II. PFD Structure and Layout

- Use a standard template or format : Establish a consistent structure and layout for your PFD to ensure clarity and ease of understanding.

- Keep it simple and concise : Avoid clutter and focus on the essential process steps and information.

- Use clear and concise labels : Label each process step, instrument, and equipment clearly and concisely.

III. Process Steps and Activities

- Identify and include all process steps : Ensure that all process steps, including manual and automated activities, are included in the PFD.

- Describe each process step clearly : Provide a brief description of each process step, including any relevant details or conditions.

- Indicate process step relationships : Show the relationships between process steps, including sequencing, parallel activities, and decision points.

IV. Instrumentation and Automation

- Include all instruments and automation components : Identify and include all instruments, sensors, actuators, and automation components in the PFD.

- Specify instrument and automation details : Provide details about each instrument and automation component, including its function, type, and tag number.

- Show instrument and automation connections : Illustrate the connections between instruments, sensors, actuators, and automation components.

V. Material and Energy Flows

- Show material flows : Illustrate the flow of materials, including inputs, outputs, and intermediate products.

- Indicate energy flows : Show the flow of energy, including utilities, such as electricity, steam, and water.

- Highlight potential hazards: Identify and highlight potential hazards, such as toxic substances, high temperatures, or explosive environments.

VI. Control and Monitoring

- Indicate control systems and strategies : Show the control systems and strategies used to regulate the process, including feedback loops and control algorithms.

- Specify monitoring and alarm points : Identify monitoring points and alarm conditions to ensure process safety and efficiency.

VII. Error Prevention and Quality Control

- Identify potential error sources : Highlight potential error sources, such as human error, equipment failure, or process deviations.

- Include quality control checks : Show quality control checks and inspections to ensure process quality and product integrity.

VIII. Review and Validate

- Review the PFD with stakeholders: Review the PFD with operators, maintenance personnel, engineers, and other stakeholders to ensure accuracy and completeness.

- Validate the PFD against actual process data : Validate the PFD against actual process data to ensure it accurately represents the process.

By following these guidelines, you can create a comprehensive and accurate Process Flow Diagram that effectively communicates the process and its requirements to all stakeholders involved in the process automation project.