Performance Characteristics of Francis Turbine

Procedure –

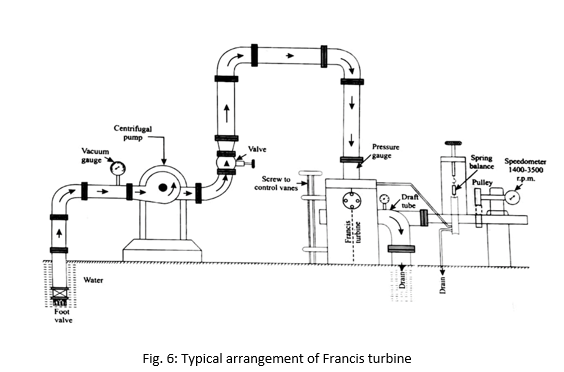

Experimental Setup

- A Francis turbine with an arrangement for adjusting the guide vane positions (hand wheel with suitable link mechanisms)

- Supply pump unit.

- Flow measurement unit (viz. venturi meter with manometer)

- Tachometer.

- Pressure gauges at the inlet and outlet of turbine.

- Rope brake dynamometer with spring balance connected to the turbine shaft.

Procedure –

- Note the inlet and outlet pipe diameters and measure the brake drum diameter and Z1 and Z2 i.e. the distances of inlet and outlet pressures gauge tappings from the centerline of the turbine.

- Start the supply pump, keeping the guide vanes completely closed

- Open the guide vanes partially (e.g. 1⁄4 or 1⁄2 of total opening),

- Measure the discharge Q

- Note the readings of pressure gauges

- Note the readings of W (load on hanger) and spring balance S and shaft speed N

- Vary speed of turbine by varying the load i.e. W and S on the brake drum and take six to seven readings in the allowable range of speed

- Change the guide vane opening and repeat steps 4 to 7

Formulae

- V1=Q/(π/4) d12

V2=Q/(π/4) d22

Where, V1 is absolute velocity of water entering

V2 is absolute velocity of water leaving

Q= discharge

d1= Dia. of Inlet pipe

d2= Dia. of outlet pipe - H= (P1/w-P2/w)+ (V12- V22/2g)+ (Z1- Z2 )

Where, Z1 = Distance of inlet pressure gauge from turbine axis

Z2 =Distance of inlet pressure gauge from turbine axis w = Specific weight of water - Input power: Pi=(w×Q×H)/75

- Output Power: Po=((W-S)×π×D×N)/4500

Where, D = Mean Diameter of the brake drum

N = Speed of motor in RPM - η=Po/Pi ×100

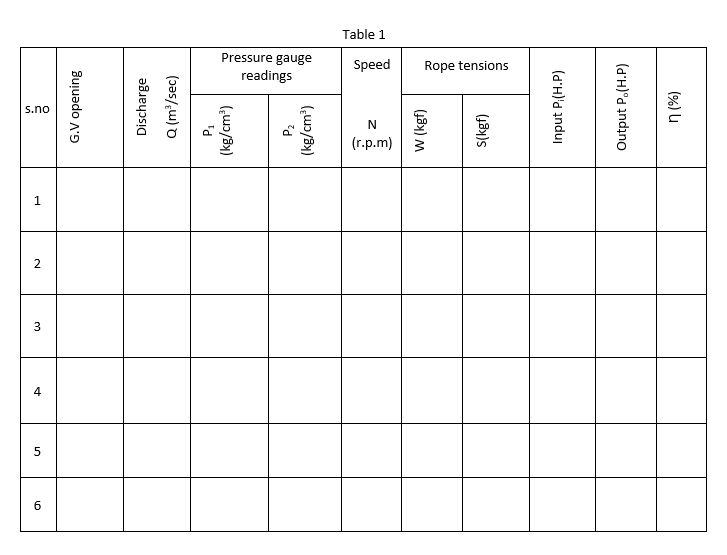

Observations -

- Mean Diameter of the brake drum, D(Dd + Dr) =

Where Dd = diameter of the drum, Dr = diameter of rope

- Dia. of Inlet pipe, d1 = 65 mm

- Dia. of outlet pipe, d2 = 38.45 mm

- Distance of inlet pressure gauge from turbine axis Z1 =

- Distance of inlet pressure gauge from turbine axis Z2 =

- Venturi meter constant, k = 35.7 Q=k √h

Calculations

- V1=Q/((π/4) 〖d1〗2 ) V2=Q/((π/4) 〖d2〗2 )

- H= (P1/w-P2/w)+ (〖V1〗2- 〖V2〗2/2g)+ (Z1- Z2 )

- Input power: Pi=(w×Q×H)/75

- Output Power: Po=((W-S)×π×D×N)/4500

- η=Po/Pi ×100

- Plot the following curves and determine the efficiency of the Francis turbine

a. Efficiency Vs. Speed

b. Efficiency Vs. Power Output