Static modulus of elasticity of Concrete in compression

Objective:

To determine the static modulus of elasticity of hardened concrete in compression

Apparatus used:

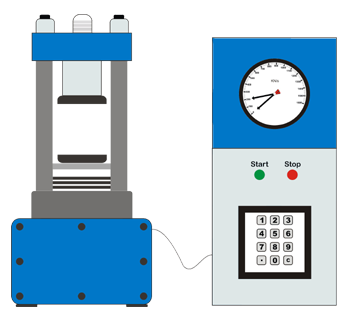

Compression testing machine, extensometer or strain gauges

STEP

1

Provide Specimen Details

Enter the date of casting of specimens:

DaysSelect the size of cube specimens:

cm| Age of specimen | |

| Size of specimen | |

| Cross sectional area, Ac | |

| Number of specimen |

STEP

1

Determine the compressive strength of concrete

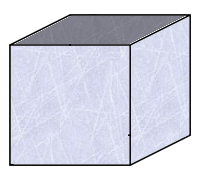

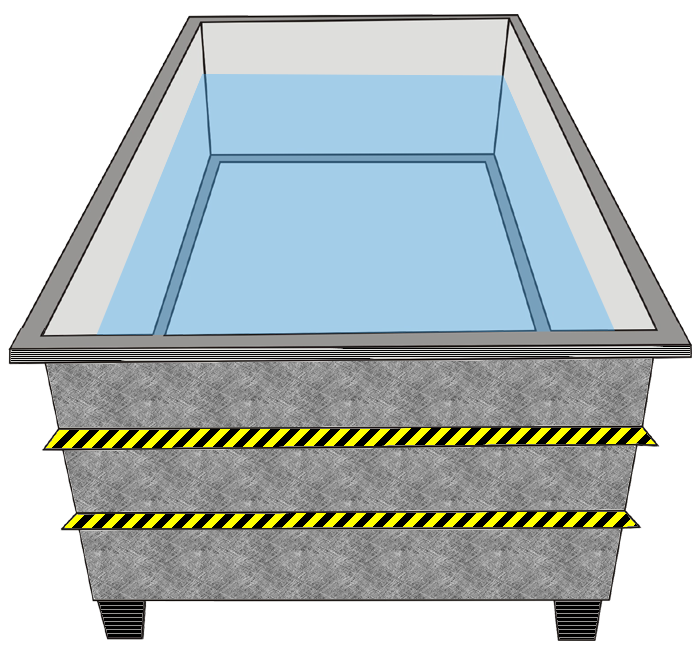

Take out three cube specimens of size 150X150X150 from the curing tank.

Click on the cloth to wipe the surface of the samples to remove the excess moisture.

STEP

4

Specimen 1

Clean the bearing surfaces of the CTM before positioning of the specimens.

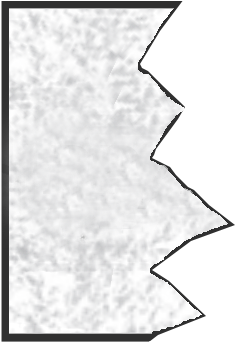

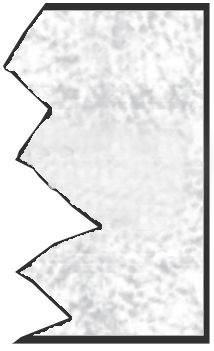

Place the specimen in the CTM. Cube specimens shall be compressed perpendicularly to the direction of casting.

Place the specimen in the CTM. Cube specimens shall be compressed perpendicularly to the direction of casting.

STEP

5

Specimen 1

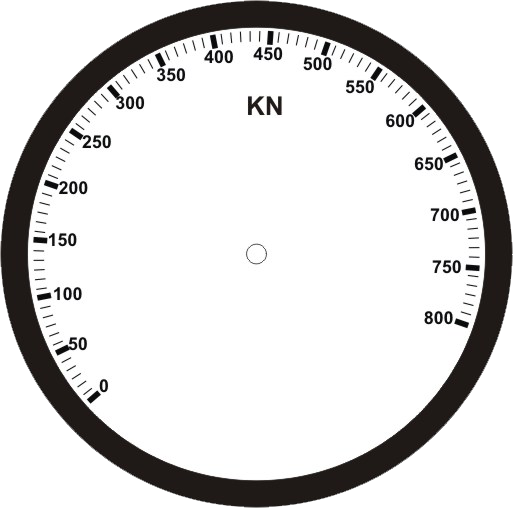

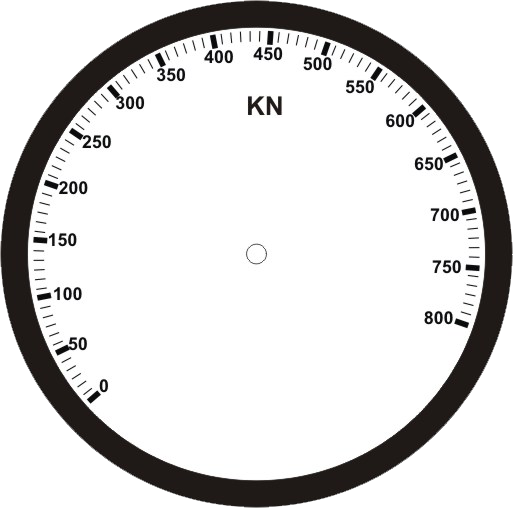

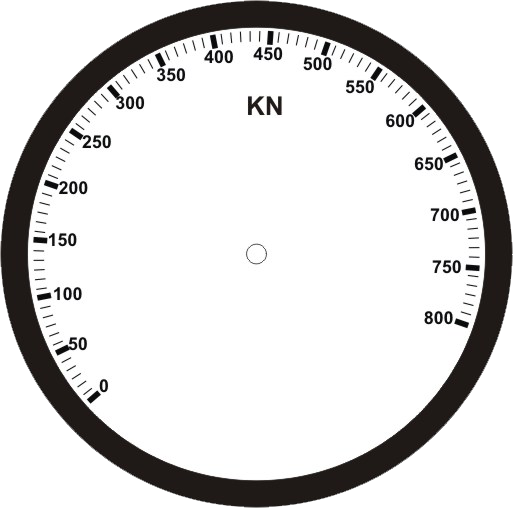

Click on CTM panel to enter the rate of loading.

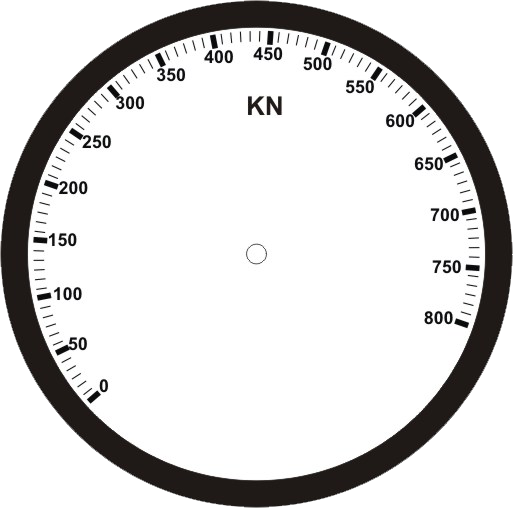

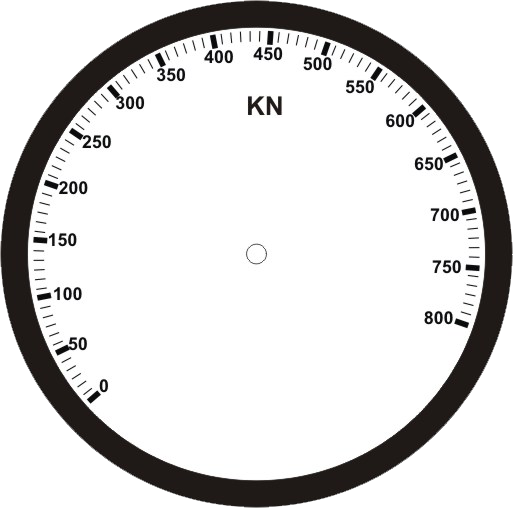

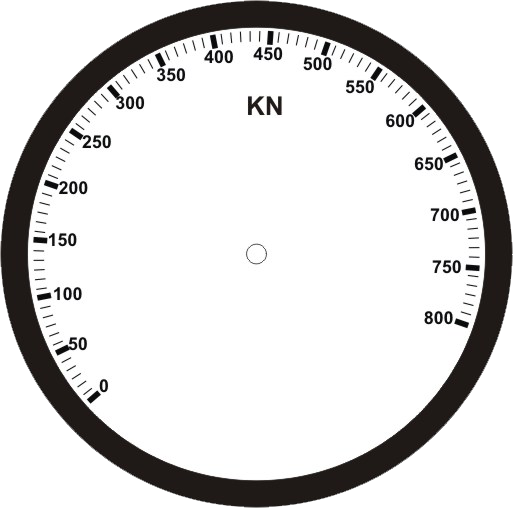

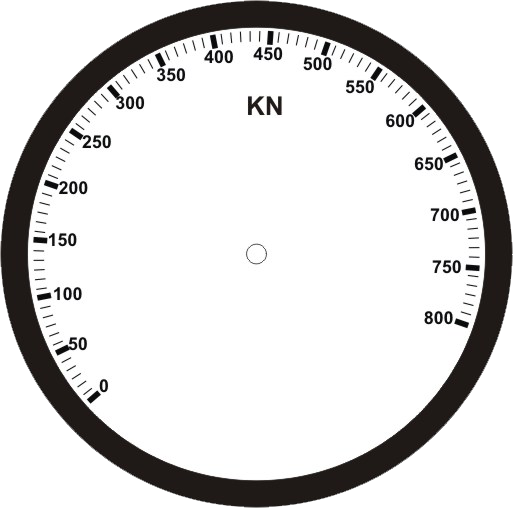

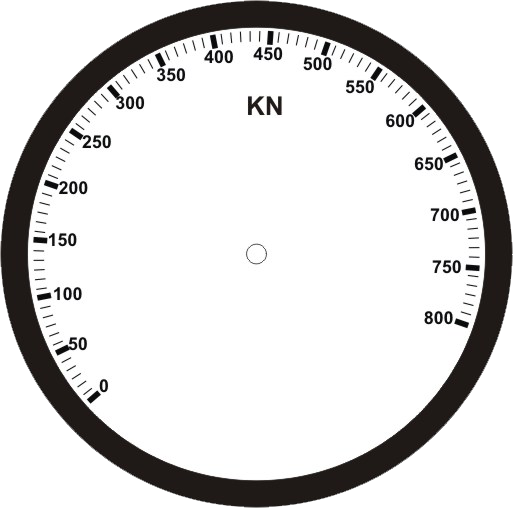

KN

STEP

6

Specimen 1

Step 1: Click on the dial of CTM for zoomed view.

Step 2: Click Start button of CTM to initiate the test.

Step 3: Click Stop Button to see Values

Click Next to Repeat test for other two specimen.

| Load at failure: | KN | |

| Time: | sec. |

STEP

7

Specimen 2

Clean the bearing surfaces of the CTM before positioning of the specimens.

Place the specimen in the CTM. Cube specimens shall be compressed perpendicularly to the direction of casting.

Place the specimen in the CTM. Cube specimens shall be compressed perpendicularly to the direction of casting.

STEP

8

Specimen 2

Click on CTM panel to enter the rate of loading.

KN

STEP

9

Specimen 2

Step 1: Click on the dial of CTM for zoomed view.

Step 2: Click Start button of CTM to initiate the test.

Step 3: Click Stop Button to see Values

Click Next to Repeat test for third specimen.

| Load at failure: | KN | |

| Time: | sec. |

STEP

10

Specimen 3

Clean the bearing surfaces of the CTM before positioning of the specimens.

Place the specimen in the CTM. Cube specimens shall be compressed perpendicularly to the direction of casting.

Place the specimen in the CTM. Cube specimens shall be compressed perpendicularly to the direction of casting.

STEP

11

Specimen 3

Click on CTM panel to enter the rate of loading.

KN

STEP

12

Specimen 3

Step 1: Click on the dial of CTM for zoomed view.

Step 2: Click Start button of CTM to initiate the test.

Step 3: Click Stop Button to see Values

Click Next to Repeat test for third specimen.

| Load at failure: | KN | |

| Time: | sec. |

STEP

13

Observations:

Click the show button to see the observations for all the three specimens.

| Load at failure of Specimens (F) | ||

| Specimen 1 | Failure Load: | |

| Specimen 2 | Failure Load: | |

| Specimen 3 | Failure Load: | |

| Compressive stress at failure (fc = F/Ac) | ||

| Specimen 1 | MPa(N/mm2) | |

| Specimen 2 | MPa(N/mm2) | |

| Specimen 3 | MPa(N/mm2) | |

STEP

14

Results:

Click view button to see the results.

Click Next to Repeat Test with Specimen 3.

| Compressive Stress at Failure(fc) | fca ± 0.15 fca | Check: fc − 0.15 fca < fc < fc + 0.15 fca | |

| Specimen 1 | |||

| Specimen 2 | |||

| Specimen 3 | |||

| Average, fca | |||

| Result : Average Compressive Strangth = | |||

STEP

10

Specimen 3

Clean the bearing surfaces of the CTM before positioning of the specimens.

Place the specimen in the CTM. Cube specimens shall be compressed perpendicularly to the direction of casting.

Place the specimen in the CTM. Cube specimens shall be compressed perpendicularly to the direction of casting.

STEP

11

Specimen 3

Click on CTM panel to enter the rate of loading.

KN

STEP

12

Specimen 3

Step 1: Click on the dial of CTM for zoomed view.

Step 2: Click Start button of CTM to initiate the test.

Step 3: Click Stop Button to see Values

Click Next to Repeat test for third specimen.

| Load at failure: | KN | |

| Time: | sec. |

STEP

1

Determine the compressive strength of concrete

Test three cube specimens in CTM and determine the average value of compressive strength

Convert the cube strength to an equivalent cylinder strength (Fc).

Click Next

| Specimen | Failure Load (kN) | Area( mm2 ) | Compressive strength (MPa) = load/area |

| Specimen 1 | |||

| Specimen 2 | |||

| Specimen 3 | |||

| Result : Average Cube Strangth = | |||

| Equivalent cylinder strength (Fc)=0.8*average cube strength | |||

STEP

14

Report Size of specimen= Date of Specimen=

Report Size of specimen= Date of Specimen=

| No. | Age in days | Date of testing | Load at failure (KN): | Compressive Stress at Failure(fc) | Avg. value MPa(N/mm2) | Result |

| Specimen 1 | ||||||

| Specimen 2 | ||||||

| Specimen 3 | ||||||

| Specimen 3* |