Static modulus of elasticity of Concrete in compression

STEP

1

Objective:

To determine the static modulus of elasticity of hardened concrete in compression

Apparatus used:

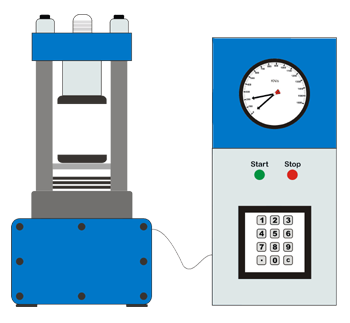

Compression testing machine, extensometer or strain gauges

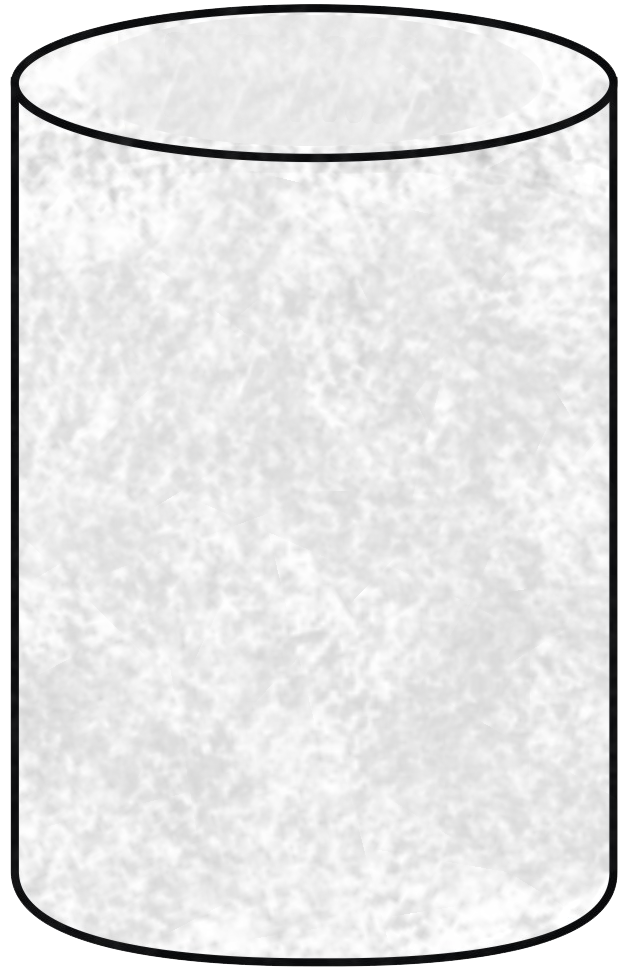

Specimen Type

Cylinder

STEP

2

Provide Specimen Details

Enter the Age of specimen:

DaysSelect the Diameter(D) of the Specimen:

mmSelect the Length(L) of the Specimen:

mm| Age of specimen | |

| Diameter of specimen, mm | |

| Length of specimen, mm | |

| Number of specimens |

STEP

2

Preparation of cylinder specimens

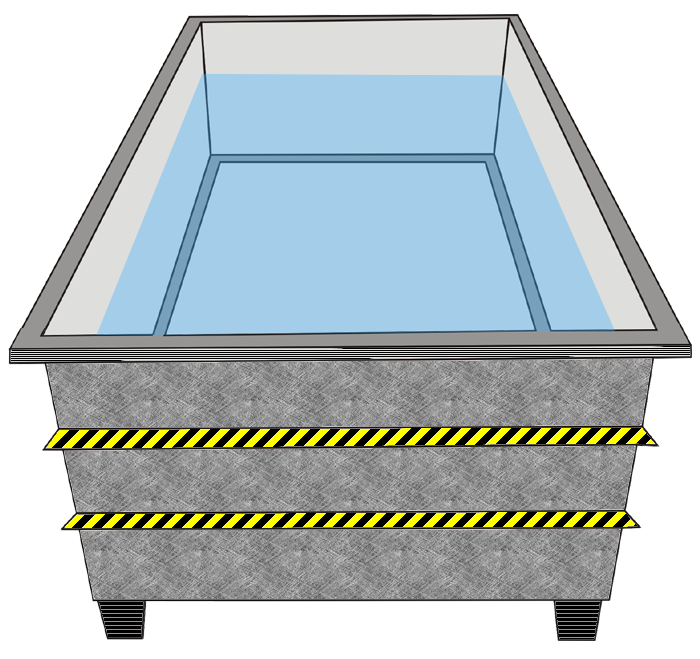

Take out three cylinder specimens of size 300X150 from the curing tank.

Click on the cloth to wipe the surface of the samples to remove the excess moisture.

STEP

3

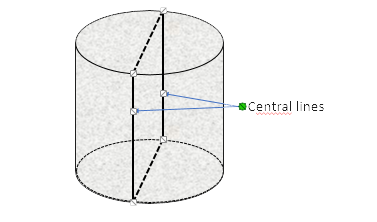

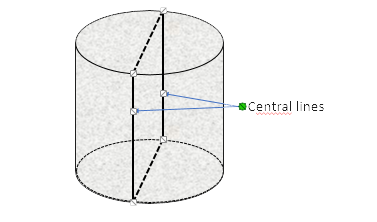

a). Using a marker, central lines shall be drawn on the two opposite faces.

Note: Ensure that they are in the same axial plane.

Note: Ensure that they are in the same axial plane.

STEP

2

Preparation of cylinder specimens

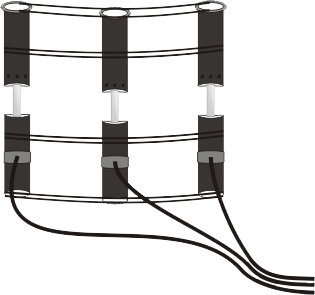

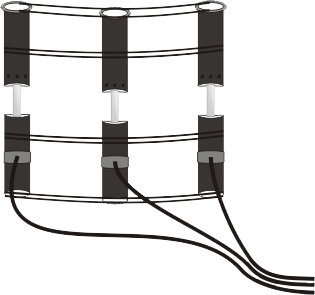

While in the wet condition, attach the extensometers (three equidistant from each other) in the

longitudinal direction, parallel to the axis and symmetrical about the centre of the specimen.

Gauge length

Gauge length

longitudinal direction, parallel to the axis and symmetrical about the centre of the specimen.

Gauge length

Gauge length

STEP

3

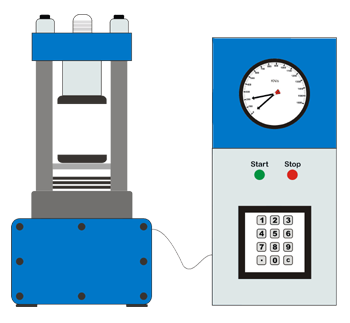

Placement of specimen in CTM

Place the specimen with the attached extensometers in the testing machine centrally.

STEP

5

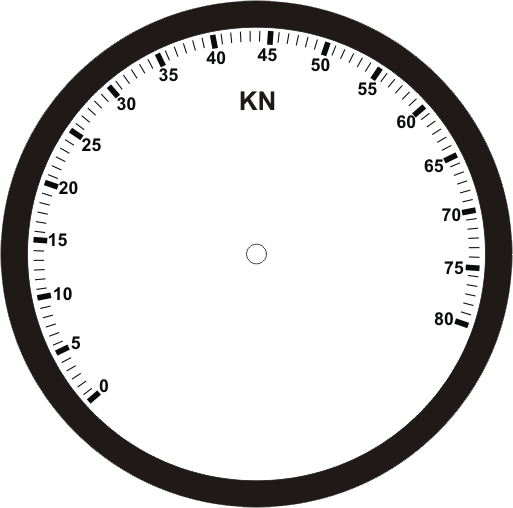

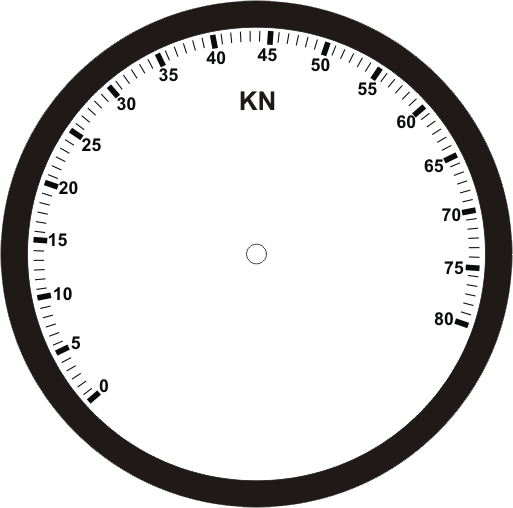

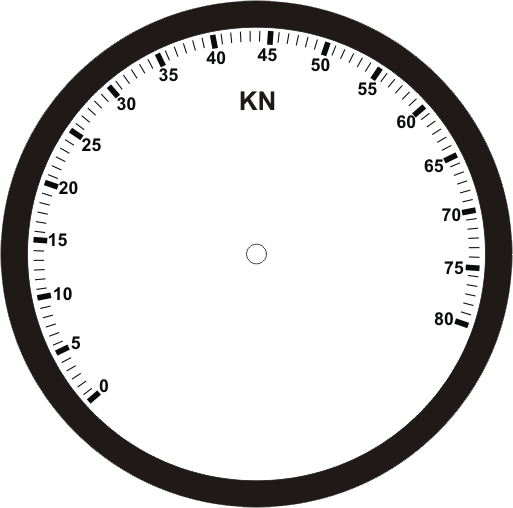

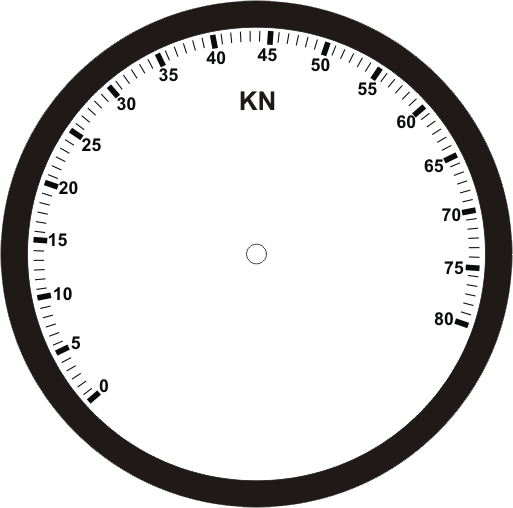

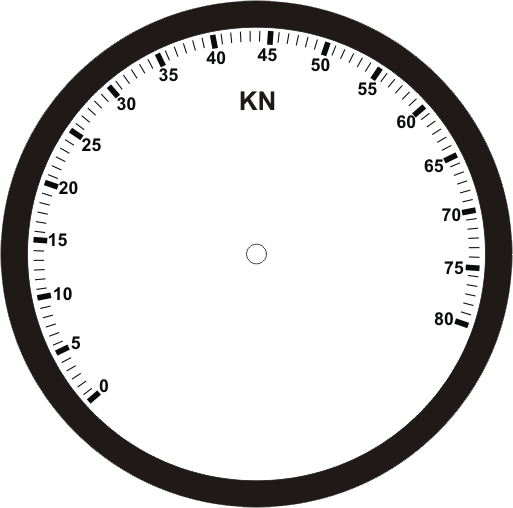

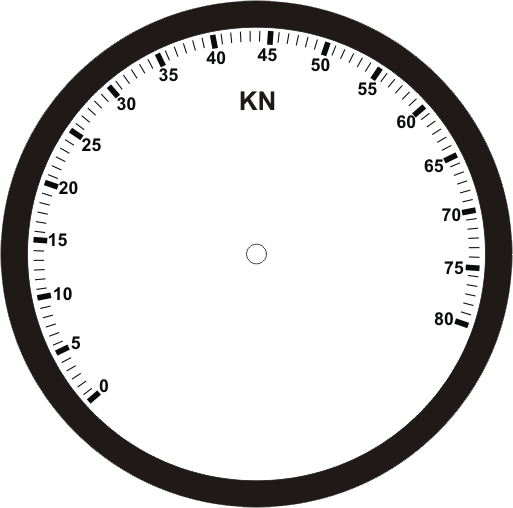

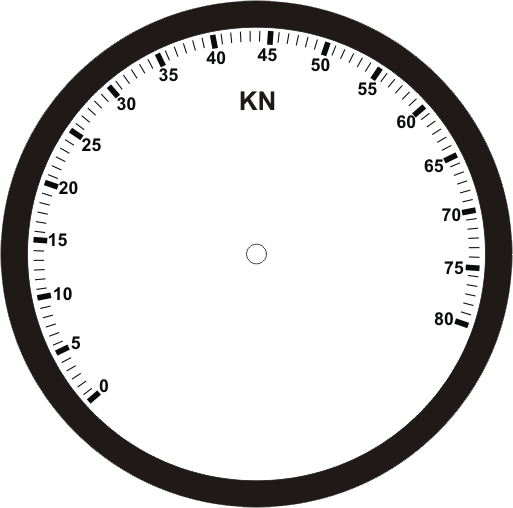

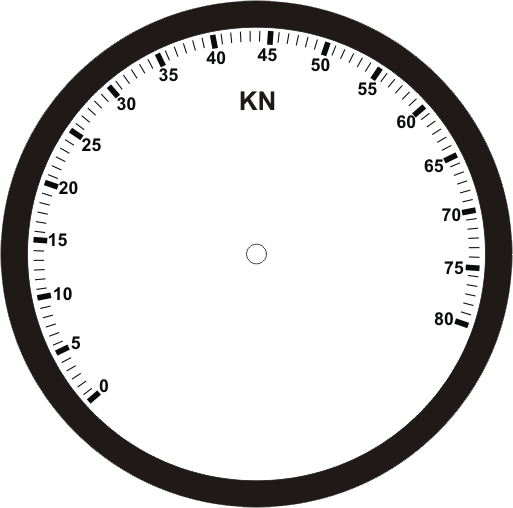

a). Click Numpad on CTM for zoom view.

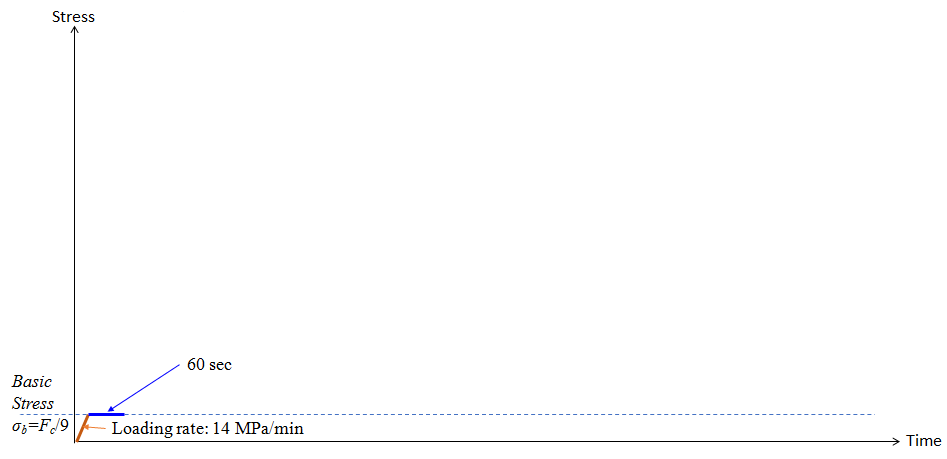

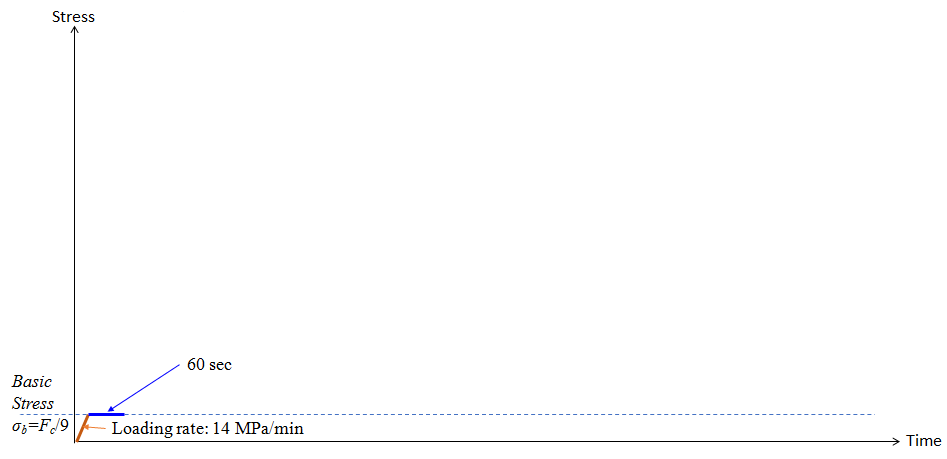

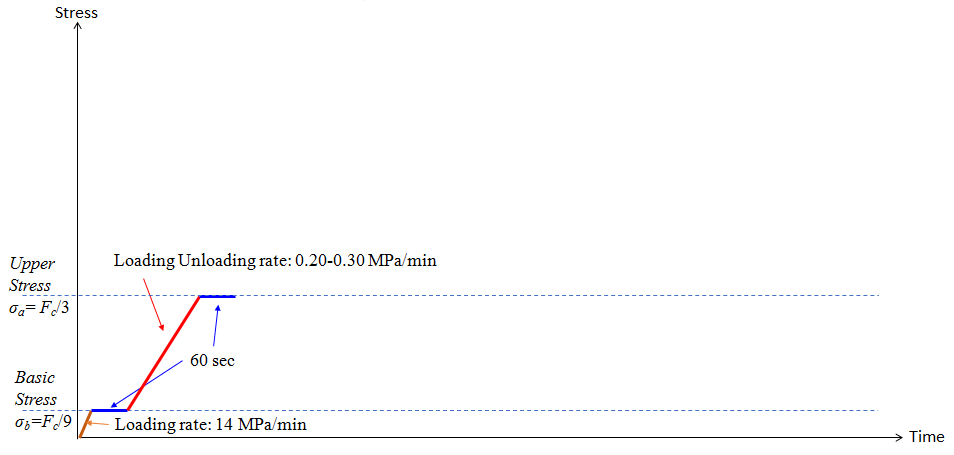

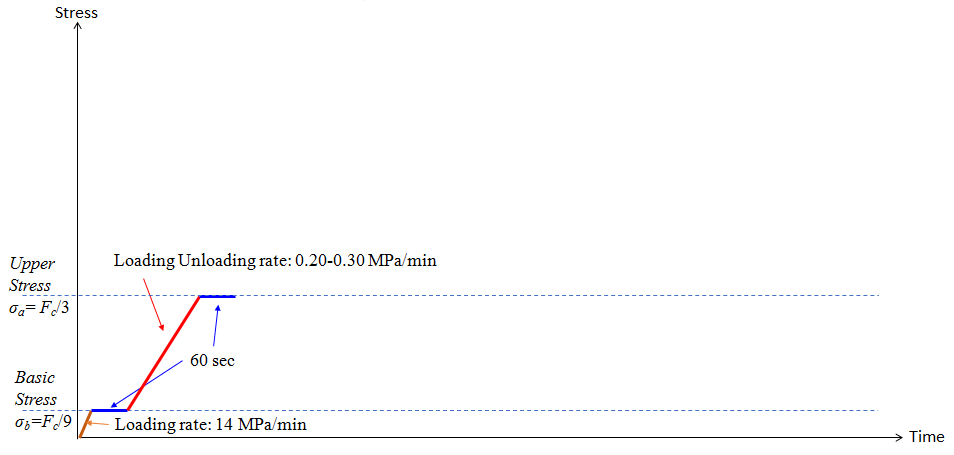

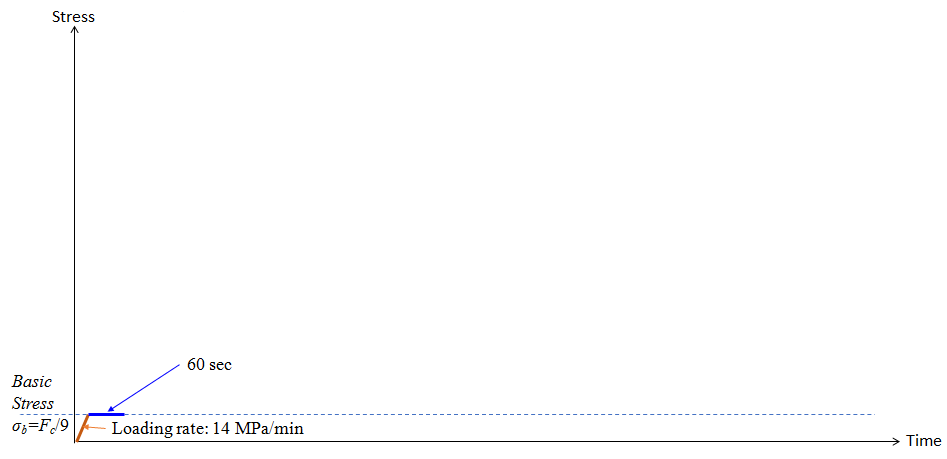

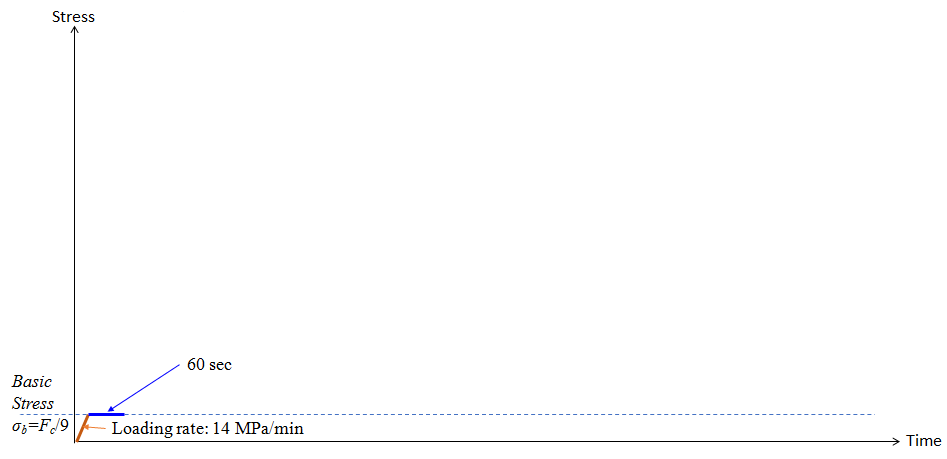

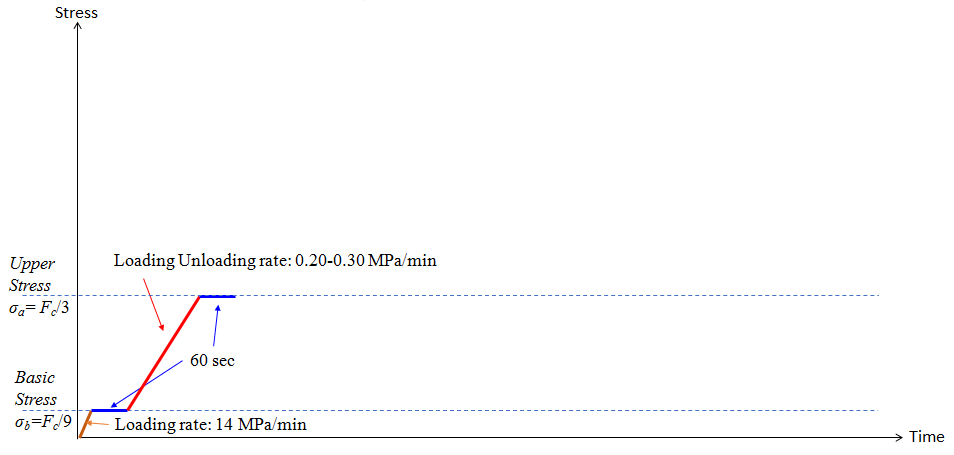

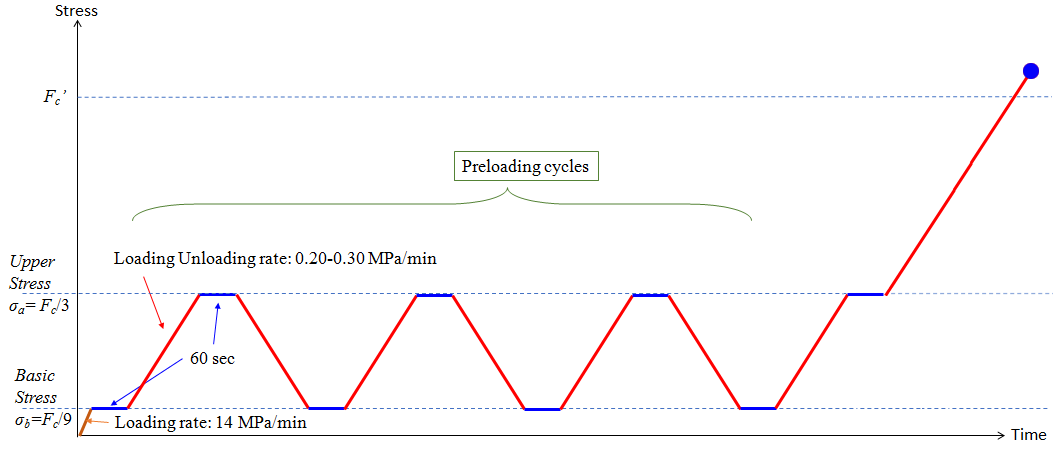

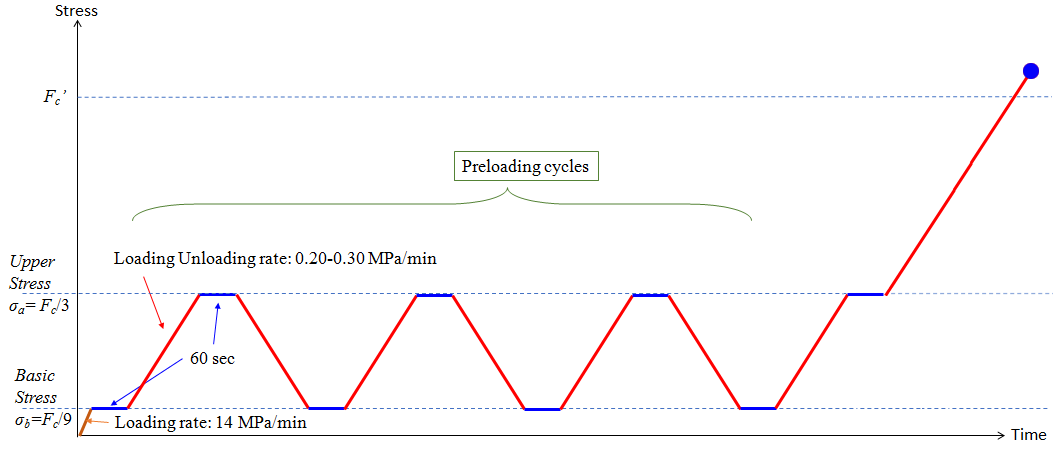

b). Apply the load continuously and without shock at a rate of 14 N/mm2/min until stress reaches Fc/9 (σb) and maintain stress Fc/9 for 60 s.

N/mm2

STEP

6

Specimen

a). Click on the dial of CTM for zoomed view.

b). Click Start button of CTM to initiate the test.

c). Apply the load continuously and without shock at a

Rate of 14 N/mm2/min until stress reaches Fc/9 (σb)

and maintain stress Fc/9 for 60 s.

Click Next to Examine the fractured specimen.

Rate of 14 N/mm2/min until stress reaches Fc/9 (σb)

and maintain stress Fc/9 for 60 s.

| Time: | sec. |

STEP

4

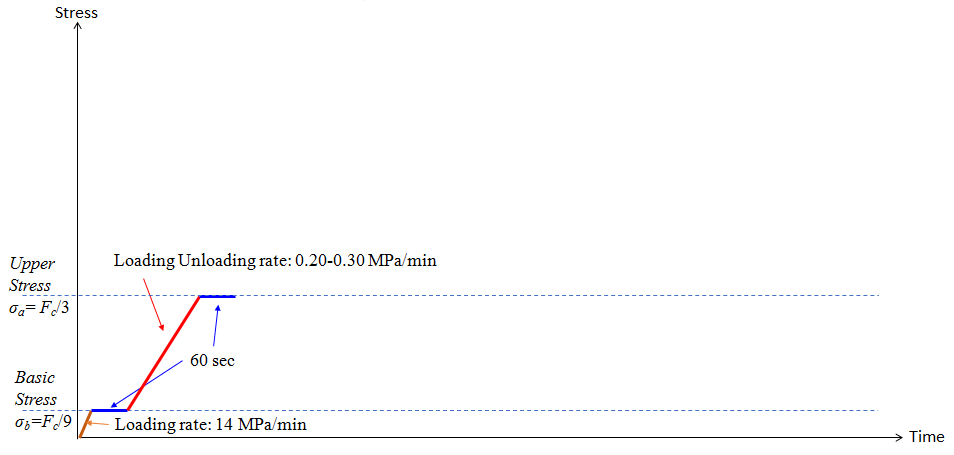

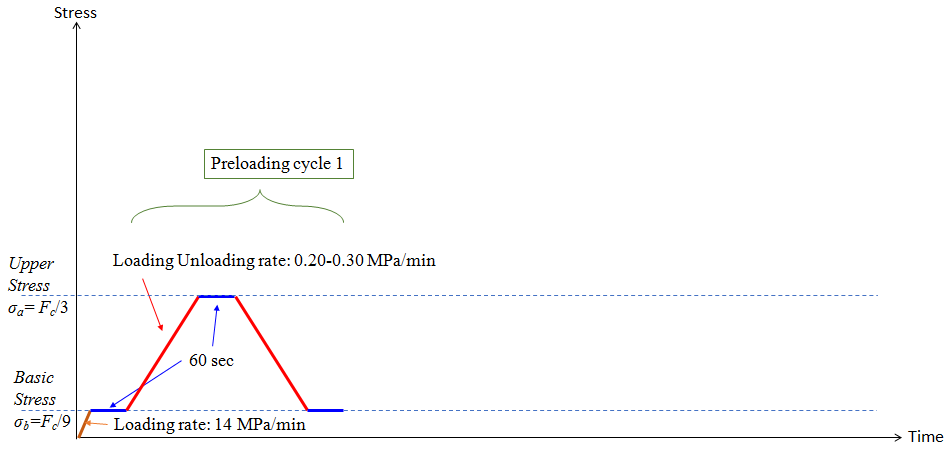

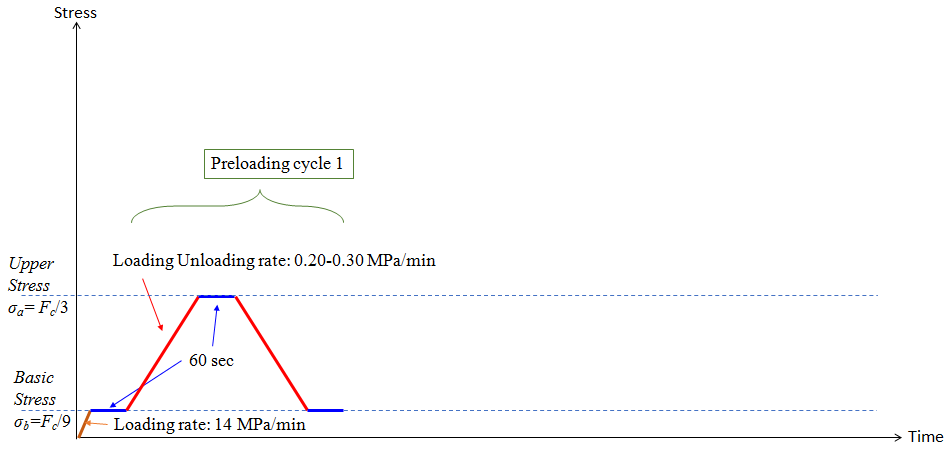

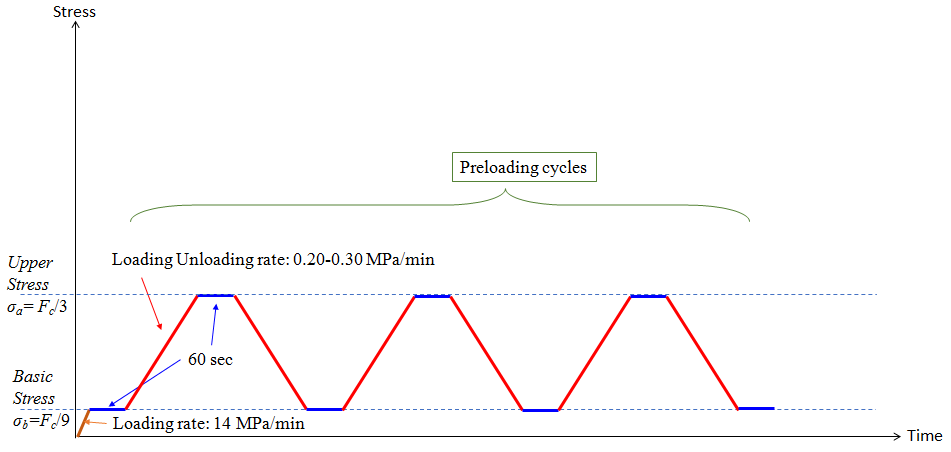

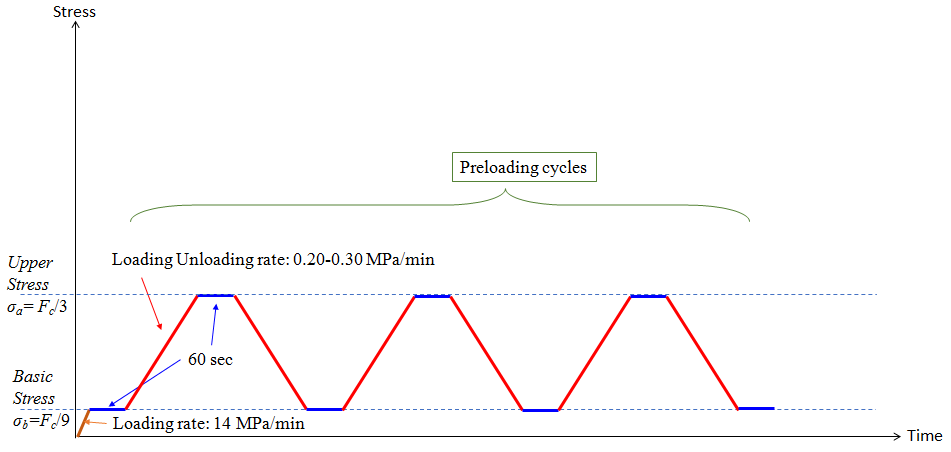

Load Application:

Apply the load continuously and without shock at a Rate of 14 N/mm2/min until stress

reaches Fc/9 (σb) and maintain stress Fc/9 for 60 s.

reaches Fc/9 (σb) and maintain stress Fc/9 for 60 s.

STEP

8

Specimen

a). Steadily increase the stress at the constant

rate within the range 0.20 N/mm2/s to 0.30 N/mm2/s

until the stress equals Fc/3 (σa) and maintain for 60s.

Click Next to Examine the fractured specimen

rate within the range 0.20 N/mm2/s to 0.30 N/mm2/s

until the stress equals Fc/3 (σa) and maintain for 60s.

| Time: | sec. |

STEP

5

Load Application:

Steadily increase the stress at the constant rate within the range 0.20 N/mm2/s to 0.30 N/mm2/s

until the stress equals Fc/3 (σa) and maintain for 60s.

until the stress equals Fc/3 (σa) and maintain for 60s.

STEP

6

Specimen Centering

During the succeeding 30 s measure and record the strain readings taken at each measurement line. If the individual strains are not within a range of ±20 percent of their mean value at σa, recenter the test specimen and repeat the test. If it is not possible to reduce the differences to within this range do not proceed with test.

| Gauge length Lo (mm) | Stress MPa | ∆L (mm) | Longitudinal strain(𝛆)=∆L/Lo | Centering check (±20%) | |||||

| Line1 | Line2 | Line3 | Line1 | Line2 | Line3 | Average | |||

| 100 | 11.55 | 0.032 | 0.036 | 0.046 | 0.00032 | 0.00036 | 0.00046 | 0.000380 | Not ok |

STEP

11

Specimen

a). Click on the specimen to recenter it.

b). Click on the dial of CTM for zoomed view.

c). Click Start button of CTM to initiate the test.

c). Apply the load continuously and without shock at a

Rate of 14 N/mm2/min until stress reaches Fc/9 (σb)

and maintain stress Fc/9 for 60 s.

Click Next to Examine the fractured specimen.

Rate of 14 N/mm2/min until stress reaches Fc/9 (σb)

and maintain stress Fc/9 for 60 s.

| Time: | sec. |

STEP

12

Specimen

STEP

13

Specimen

a). Steadily increase the stress at the constant

rate within the range 0.20 N/mm2/s to 0.30 N/mm2/s

until the stress equals Fc/3 (σa) and maintain for 60s. b). Click Start button of CTM to initiate the test. c). Steadily increase the stress at the constant

rate within the range 0.20 N/mm2/s to 0.30 N/mm2/s

until the stress equals Fc/3 (σa) and maintain for 60s.

Click Next to Examine the fractured specimen

rate within the range 0.20 N/mm2/s to 0.30 N/mm2/s

until the stress equals Fc/3 (σa) and maintain for 60s. b). Click Start button of CTM to initiate the test. c). Steadily increase the stress at the constant

rate within the range 0.20 N/mm2/s to 0.30 N/mm2/s

until the stress equals Fc/3 (σa) and maintain for 60s.

| Time: | sec. |

STEP

14

Specimen

STEP

6

Specimen Centering

After recentering

| Gauge length Lo (mm) | Stress MPa | ∆L (mm) | Longitudinal strain(𝛆)=∆L/Lo | Centering check (±20%) | |||||

| Line1 | Line2 | Line3 | Line1 | Line2 | Line3 | Average | |||

| 100 | 11.55 | 0.033 | 0.035 | 0.034 | 0.00033 | 0.00035 | 0.00034 | 0.00034 | Ok |

STEP

16

Specimen

a). When the centering is sufficiently accurate, reduce the stress at the unloading rate same as loading rate to Fc/9 and maintain for 60s.

STEP

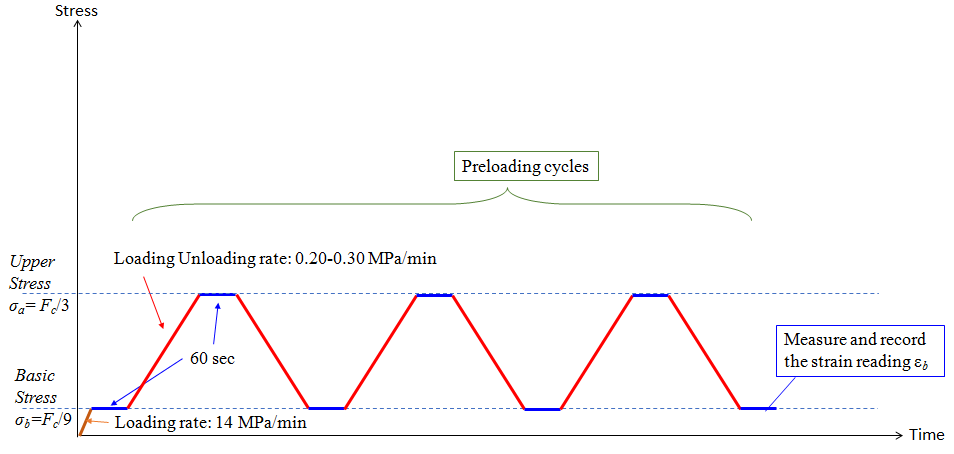

7

Preloading cycle

When the centering is sufficiently accurate, reduce the stress at the unloading rate same as loading rate to Fc/9 and maintain for 60s.

STEP

18

Specimen

a). Steadily increase the stress at the constant

rate within the range 0.20 N/mm2/s to 0.30 N/mm2/s

until the stress equals Fc/3 (σa) and maintain for 60s.

rate within the range 0.20 N/mm2/s to 0.30 N/mm2/s

until the stress equals Fc/3 (σa) and maintain for 60s.

| Time: | sec. |

STEP

8

Preloading cycle

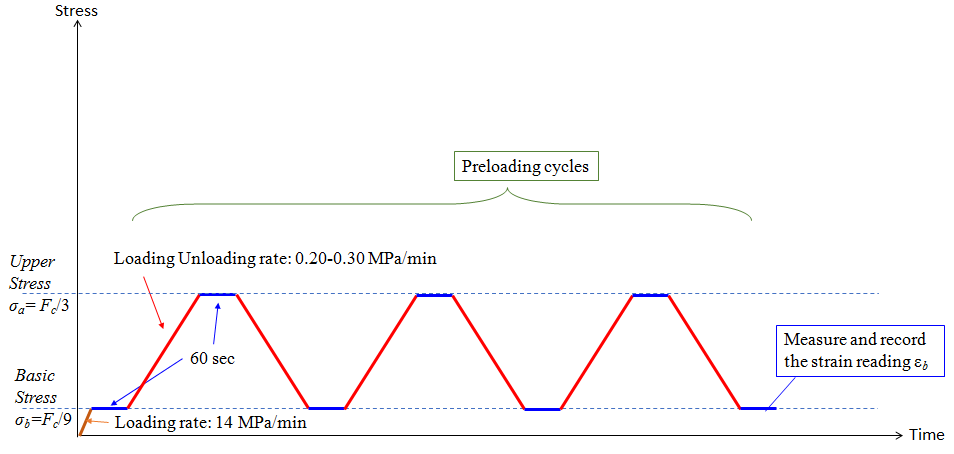

Repeat the preloading cycle for two additional loading cycles using the same loading and unloading rate, and maintaining the stress (σa and σb) constant for a period of 60 s.

STEP

9

Elasticity measurements

After completion of the last preloading cycle and a waiting period of 60 s under the stress σb = Fc/9 N/mm2,

the strain reading at the various measurement lines εb, during the succeeding 30s shall be recorded.

the strain reading at the various measurement lines εb, during the succeeding 30s shall be recorded.

STEP

9

Elasticity measurements

After completion of the last preloading cycle and a waiting period of 60 s under the stress σb = Fc/9 N/mm2,

the strain reading at the various measurement lines εb, during the succeeding 30s shall be recorded.

the strain reading at the various measurement lines εb, during the succeeding 30s shall be recorded.

| Gauge length Lo (mm) | Stress MPa | ∆L (mm) | Longitudinal strain(𝛆b)=∆L/Lo | |||||

| Line1 | Line2 | Line3 | Line1 | Line2 | Line3 | Average | ||

| 100 | 3.85 | 0.011 | 0.012 | 0.012 | 0.00011 | 0.00012 | 0.00012 | 0.000117 |

STEP

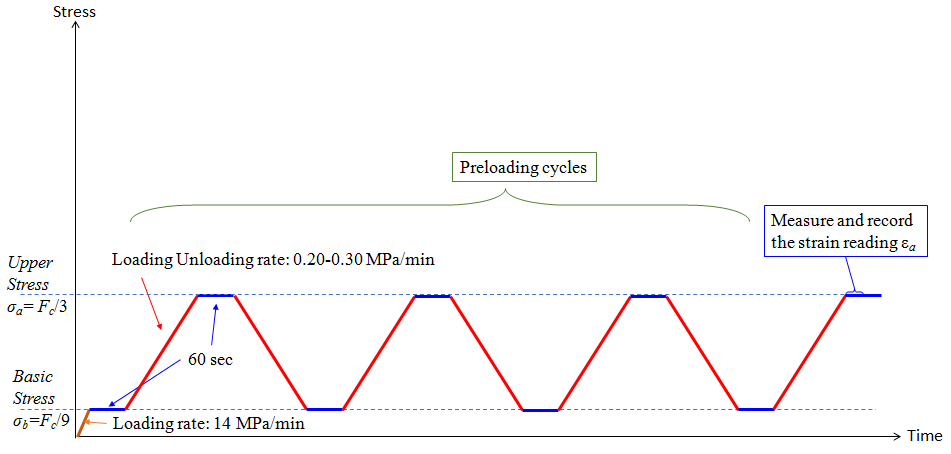

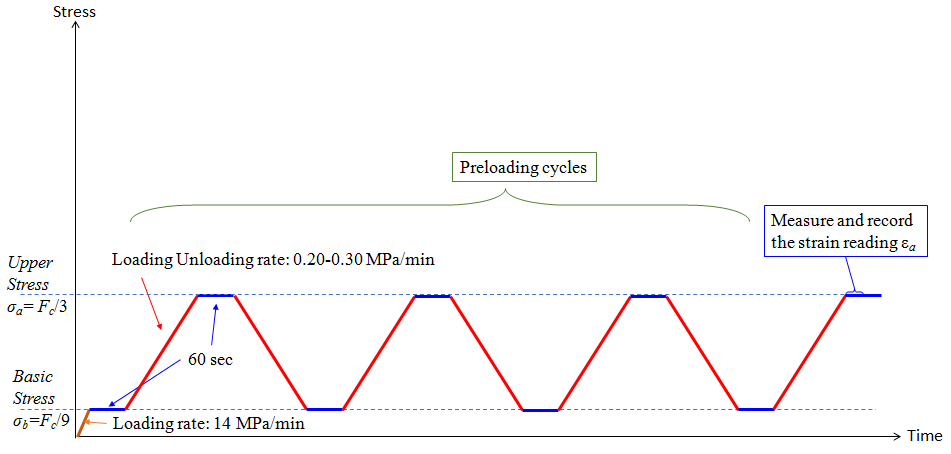

10

Elasticity measurements

Increase the stress at the constant rate until the stress equals Fc/3 maintain for 60s. During the succeeding 30s, measure and record the strain readings a taken at each measurement line εa.

STEP

10

Elasticity measurements

Increase the stress at the constant rate until the stress equals Fc/3 maintain for 60s. During the succeeding 30s, measure and record the strain readings a taken at each measurement line εa.

| Gauge length Lo (mm) | Stress MPa | ∆L (mm) | Longitudinal strain(𝛆a)=∆L/Lo | |||||

| Line1 | Line2 | Line3 | Line1 | Line2 | Line3 | Average | ||

| 100 | 11.55 | 0.034 | 0.036 | 0.035 | 0.00034 | 0.00036 | 0.00035 | 0.000350 |

STEP 24

the test specimen shall be increased, at the specified rate, until failure of the specimen occurs. b). Click Start button of CTM to initiate the test. c). Steadily increase the stress at the constant

rate within the range 0.20 N/mm2/s to 0.30 N/mm2/s

until the stress equals Fc/3 (σa) and maintain for 60s.

STEP

11

Loading to failure

When all elasticity measurements have been completed, the load on the test specimen shall be

increased, at the specified rate, until failure of the specimen occurs.

increased, at the specified rate, until failure of the specimen occurs.

STEP

11

Loading to failure

Check if stress at failure is within a range of ±20% of Fc. If not, this shall be noted in the test report and it shall be reported that the results may not be reliable.

| MPa | Stress at failure (MPa) | Failure check(±20%) |

| 34.65 | 37.12 | Okay |

STEP

12

Calculate the modulus of Elasticity

The mean strain εa and εb respectively shall be calculated and the static modulus of elasticity in compression is calculated.

| sample | Stress, MPa | Stress, MPa | Strain, 𝛆a | Strain, 𝛆b | Static modulus of elasticity, (MPa) |

| 1 | 11.55 | 3.85 | 0.000350 | 0.000117 | 33047 |

| 2 | |||||

| Average |

STEP

13

Repeat the procedure on the second specimen and take the average.

| sample | Stress, MPa | Stress, MPa | Strain, 𝛆a | Strain, 𝛆b | Static modulus of elasticity, (MPa) |

| 1 | 11.55 | 3.85 | 0.000350 | 0.000117 | 33047 |

| 2 | 11.55 | 3.85 | 0.000337 | 0.000113 | 34375 |

| Average | 33711 |

Report

| Size of cube specimen for compressive strength testing | 150X150X150 |

| Size of Cylindrical Specimen for modulus of elasticity Calculation | Diameter 150mm, Length 300mm |

| Concrete cube strength, MPa | 43.31 |

| Equivalent cylinder strength, MPa | 34.65 |

| Average Static modulus of elasticity, MPa | 33711 |

STEP

11

Specimen 3

a). Click on the dial of CTM for zoomed view.

b). Click Start button of CTM to initiate the test.

c). Click Stop Button to see Values

Click Next to Examine the fractured specimen.

| Load at Failure: | KN | |

| Time: | sec. |

STEP

12

Specimen 3

Examine the fractured specimen.

Click Next to Repeat the test.

Click Next to Repeat the test.

Fracture type

Click Next to Repeat the test.

Click Next to Repeat the test.

STEP

11

Specimen 3

a). Click on the dial of CTM for zoomed view.

b). Click Start button of CTM to initiate the test.

c). Click Stop Button to see Values

Click Next to Examine the fractured specimen.

| Load at Failure: | KN | |

| Time: | sec. |

STEP

12

Specimen 3

Examine the fractured specimen.

Fracture type

STEP

13

Observations:

Click Show button to see load at failure of samples (P), failure type.

| Specimen No. | Load at failure of samples (P) | Failure type |

| Specimen 1 | kN | |

| Specimen 2 | kN | |

| Specimen 3 | kN | |

| Specimen 3* | kN | |

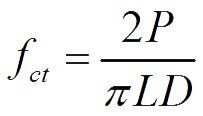

Splitting tensile strength of samples (fct)

|

||

| Specimen 1 | MPa | |

| Specimen 2 | MPa | |

| Specimen 3 | MPa | |

| Specimen 3* | MPa | |

STEP

16

Final Results:

Click View button to see Results for new specimen

Click Next to Generate Report.

| Splitting tensile strength (fct) | |

| Specimen 1 | |

| Specimen 2 | |

| Specimen 3 | |

| Specimen 3* | |

| Result: Average flexural strength = | |

STEP

17

Report

Length (L) of specimen =

Diameter (D) of specimen =

Concrete grade=

| No. | Identification mark | Age in days | Testing date | Maximum load(kN) | Failure type | Flexural strength(MPa) | Avg. value |

| 1 | |||||||

| 2 | |||||||

| 3 | |||||||

| 4 |

STEP

17