FBD for autoclavable laboratory fermenter

A fermenter is a manufactured or engineered system that supports a biologically active environment. It is a vessel in which a biological process is carried out which involves organisms or biochemically active substances obtained from such organisms. These substances comprise of food products, enzymes, drugs, alcohols, a biomass etc. These products are consumed in one or other form which demands for the level of sterility as per the FDA standards.

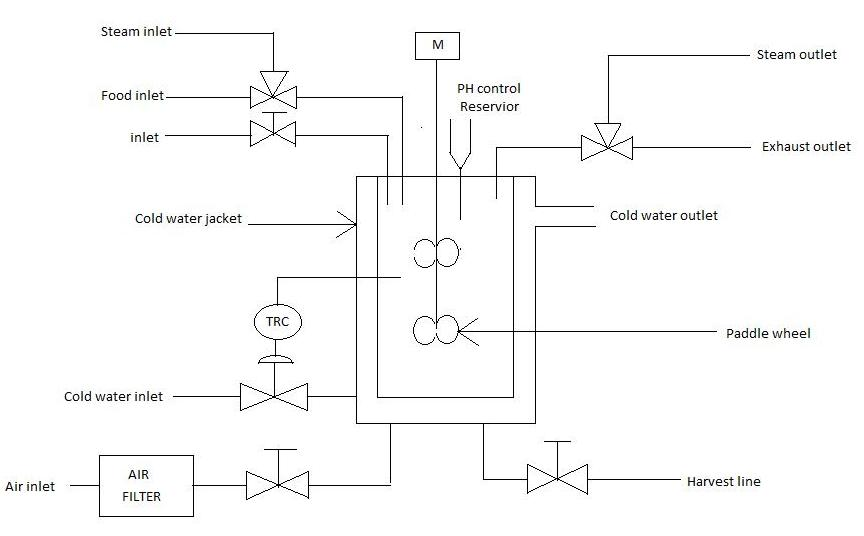

An autoclave is a system, distinct from the fermenter unit, in which the vessel and the culture medium is sterilized by subjecting it to high pressure saturated steam at 121°C for a durations that varies with the capacity and size of the unit. Physically, it is a table top scaled down model designed for the laboratory application. Hence, the name Autoclavable Laboratory Fermenter. The fermenter along with its accessories is shown here.

Need of Automatic Control for the fermenter

Large amount of heat is generated as the fermentation process proceeds from start to completion. It involves living matter so the process demands accurate control of temperature. The ratio of the heat transfer capacity to the metabolic heat generation rate is less which results in low productivity in case of pilot scale, hence there is a need for automatic control system.

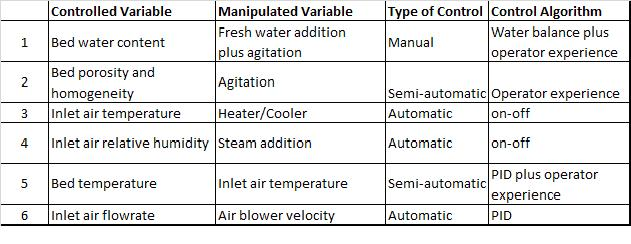

The table below shows the different controlled variables, the related manipulated variables, the type of control used and the control algorithm for the bioreactor.

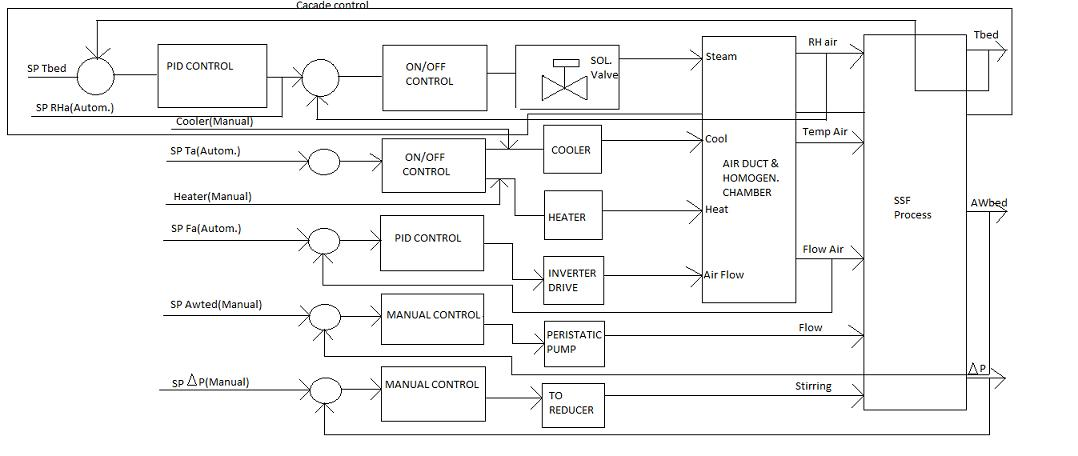

Following diagram explains various control strategies that can be implemented for the fermenter.