Age Hardening in Aluminum Alloys

1. Brief Description of the Equipment/Machine

For heat treatment, a furnace is required. For hardness measurement, a Vickers hardness tester is to be used.

2. Theory

Precipitation-hardening, or age-hardening, is a very versatile method of strengthening certain metallic alloys. The aging treatment involves the precipitation of a series of metastable and stable precipitates out of a homogeneous, supersaturated solid solution. Various metastable structures offer different levels of resistance to dislocation motion leading to strengthening. One of the oldest precipitation hardenable aluminum alloy is Duralumin, which generally consists of alloying elements like copper, manganese, magnesium in aluminum.

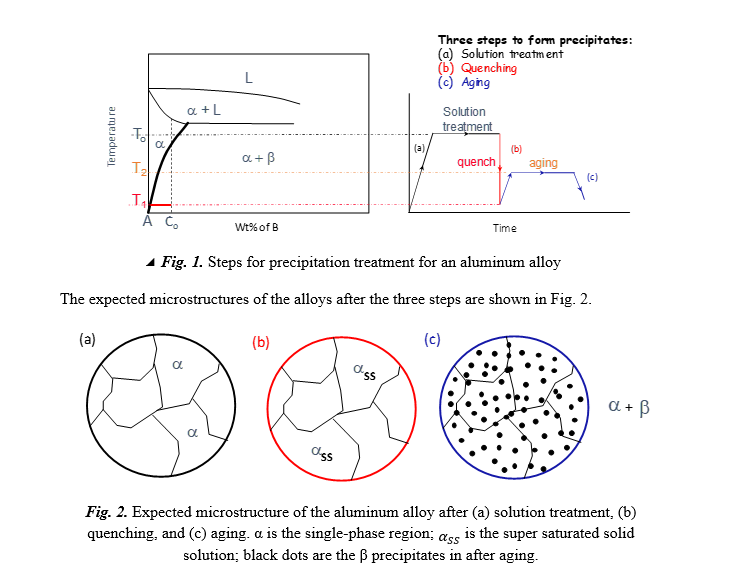

Fig. 1 shows the steps involved in the precipitation treatment for an aluminum alloy of composition Co. The steps are:

√ Solution Treatment

This involves heating the alloy to the single-phase region and maintaining it there for a sufficiently long time to dissolve any soluble precipitates. In the phase diagram, it involves heating at temperature To.

√ Quenching

This involves cooling the single-phase alloy very rapidly to room temperature or lower so that the formation of stable precipitates is avoided. Thus, one obtains a supersaturated solid solution. In this process, the sample has been quenched from To to T1.

√ Aging

This treatment consists of leaving the supersaturated solid solution at room temperature or at a slightly higher temperature (in the two-phase region). It results in the appearance of fine-scale precipitates. This involves heating to a temperature of T2.

A general aging sequence is as follows

supersaturated solid solution → transition structures → aged phase. The change in the hardness of a material during age hardening is due to the formation of a sequence of metastable precipitates, which are coherent or semi-coherent with the matrix (discussed later). In 1903, a researcher Wilm observed that when the Aluminium alloy (containing 4% copper) is heated above the solvus temperature and quenched, then it can exhibit “natural” ageing at room temperature or an accelerated ageing if aged “artificially” at elevated temperature. Another important hardenable alloy is 7075 aluminum alloys (Al-Zn-Mg-Cu). The sequence of various transition phases during precipitation in Duralumin is GP zones → θ″ → θ′ → θ (CuAl2). The widely accepted precipitation sequence of Al7075 alloy during aging is: supersaturated solid solution (SSSS)* GP zones * η’ * η. With the aging process, the size of the precipitates increases and the nature of the interface between the precipitates and the matrix also changes.

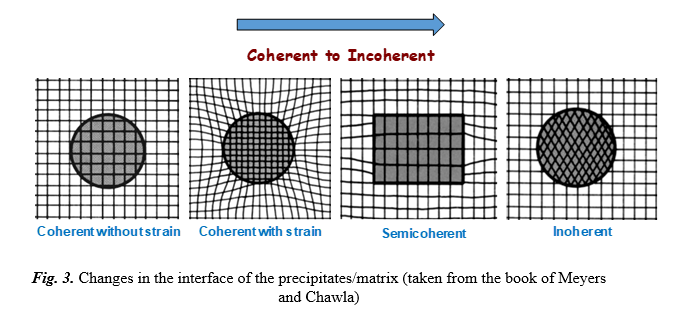

The nature of the precipitate/matrix interface produced during the aging treatment can be coherent, semicoherent, or incoherent (Fig. 3). Coherency signifies that there exists a one-to-one correspondence between the precipitate lattice and that of the matrix. (See Figure 3). A semicoherent precipitate signifies that there is only partial correspondence between the two sets of lattice planes. The lattice mismatch is accommodated by the introduction of dislocations at the noncorrespondence sites. An incoherent interface (Fig. 3) implies that there is no correspondence between the two lattices. Such an interface is also present in dispersion-hardened systems.

In the initial stages of the aging treatment, zones that are coherent with the matrix appear. These zones are nothing but clusters of solute atoms on certain crystallographic planes of the matrix. The zones are transition structuring and are referred to as Guinier-Preston zones, or GP zones, in honor of the two researchers who first discovered them. We call them zones rather than precipitates to emphasize that the zones represent a small clustering of solute atoms that have not yet taken the form of precipitate particles. The GP zones are very small and have a minimal lattice mismatch with the aluminum matrix. Thus, they are coherent with the matrix; that is, the lattice planes cross the interface in a continuous manner. Such coherent interfaces have very low energies, but there are small elastic coherency strains in the matrix. As these coherency strains grow, the elastic energy associated with them is reduced by the formation of semicoherent zones where dislocations form at the interface to take up the misfit strain. Further growth of the semicoherent zones, or precipitates, results in a complete loss of coherency: An incoherent interface forms between the precipitate and the matrix.

Interaction of dislocations with precipitates

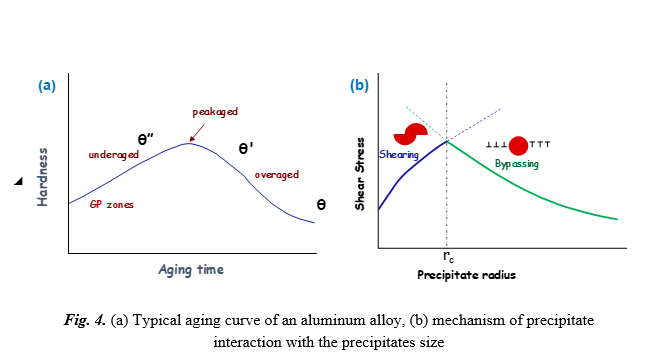

Overall, with the aging time the size of the precipitates increases and the interface changes from coherent to incoherent. Therefore, the nature of dislocation interaction with the precipitates also changes with the aging time. The dislocations generally tend to shear the precipitates, which are smaller and coherent. The stress required for shearing varies proportional to the radius (r) of the precipitates. In contrast, dislocations bypass the precipitates when the size of the precipitates is large and they are incoherent. In this case, the stress required to bypass the dislocations is inversely proportional to √r.

The aging curve

After aging treatment, samples are subjected to Vickers hardness measurement. The typical shape of the aging curve is shown in Fig. 4a, where the hardness is observed to first increase and then decrease with aging time. The alloy with the highest hardness corresponds to the peak-aged condition. Below and above this hardness/time, the alloy is in under-aged and over-aged conditions, respectively. The shape of the aging curve (Fig. 4a) can be explained as follows: Immediately after quenching, only solid-solution-hardening is present. As GP zones form, hardness or strength increases because extra stress is needed to make dislocations shear the coherent zones. The hardness increases as the size of the GP zones increases (as stress is proportional to (r)), making it even more difficult for the dislocations to shear the zones. As time goes on, incoherent equilibrium precipitates start appearing, and the mechanism of Orowan bowing (bypassing) of dislocations around the precipitates becomes operative. Thus, in the initial aging time (under-aged condition), shearing of the precipitates dominates over bypassing of the dislocations (Fig. 4b). At the later stage of aging (over-aged condition), bypassing of the dislocations dominates over shearing. The peak hardness or strength is associated with a critical dispersion of coherent or semicoherent precipitates. Further aging increases the interparticle distance, and a lower strength results as dislocation bowing becomes easier.

Fig. 5 shows the evolution of precipitates with time in Al-Cu alloys [1]. One can observe that the size of precipitates increases with aging time. Fig. 6 shows cutting of precipitates by dislocations and bypassing of dislocations [2].

Fig. 5 Microstructure at different stages during aging of Al-Cu alloys

Fig. 6 Cutting of precipitates by dislocations and bypassing of dislocations and loop formation

[1] David A. Porter, Kenneth E. Easterling, Phase Transformations in Metals and Alloys (2009)

[2] Ashby, Shercliff, Cebon, Materials: engineering, science, processing and design (2013);

Humphreys and Hatherly, Recrystallization and related annealing phenomena (2004)