TENSILE TEST ON MILD STEEL

Objective

To study the mechanical properties of mild steel specimen under tension load.

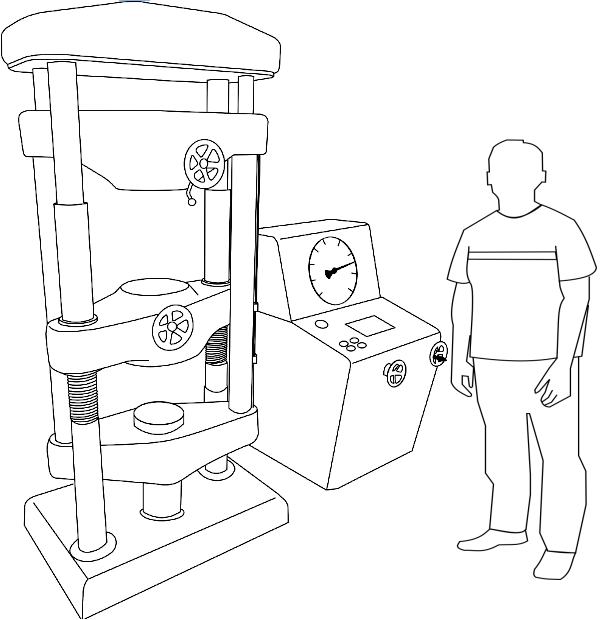

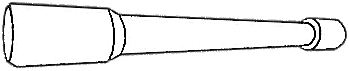

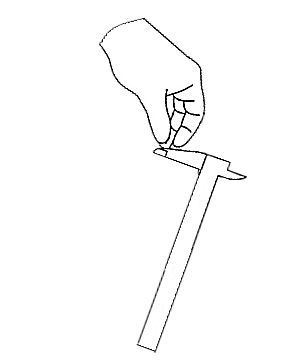

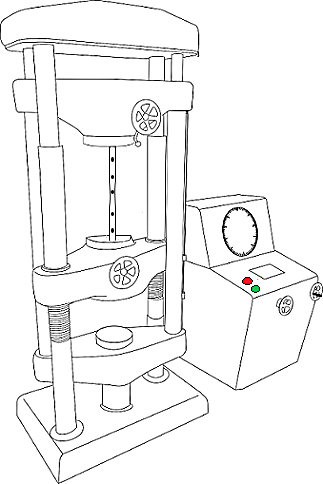

Apparatus used:

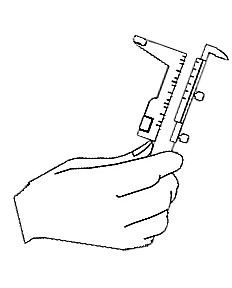

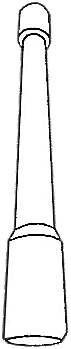

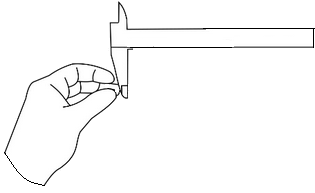

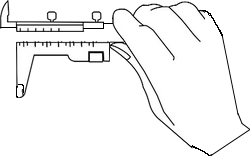

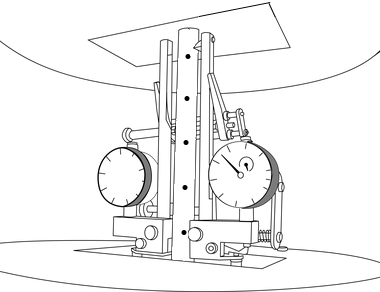

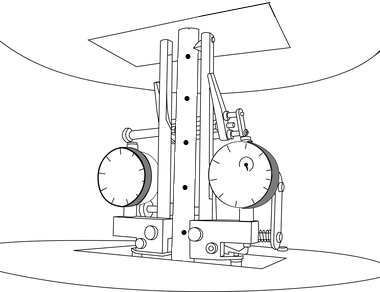

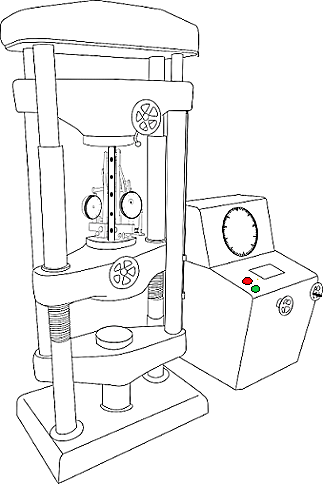

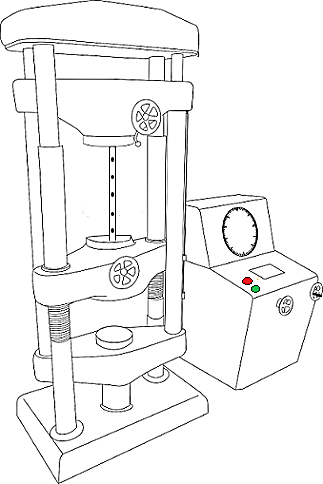

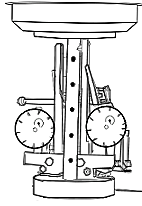

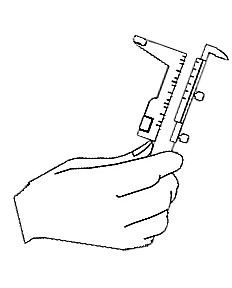

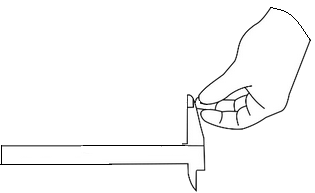

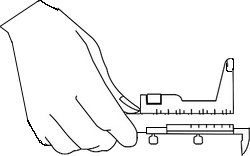

Universal Testing Machine, Dial Indicators, Extensometer, Scale & Vernier calipers.

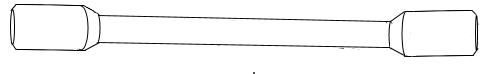

Measure the Initial Diameter of the tension test sample in two perpendicular directions using vernier caliper.

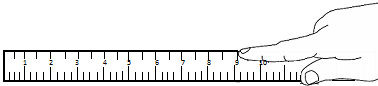

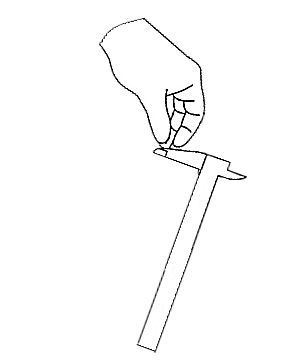

Measure the Length of the specimen between the grips using a scale.

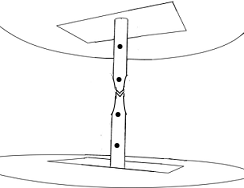

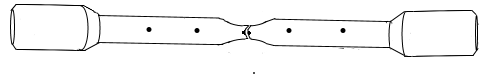

Punch marks are made at a distance of 2.5d.

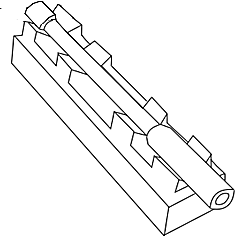

Insert the specimen into its position and mount extensometer on the specimen.

Readings on the dials A and B of extensometer are adjusted to zero.

Least Count of Extensometer = 0.01mm

Experiment is conducted. Load, extensometer readings are read at regular intervals of load upto the yield point. Ivory scale readings are noted till the specimen failure.

Graph.

Graph.

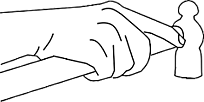

Join two pieces of the test sample and measure the diameter at the neck of the specimen.

Measure the final length between three punch marks.

Observations and Calculations.

| Initial diameter in mm | |

|---|---|

| Length of the specimen between the grips in mm | |

| Punch mark at a interval of 2.5d in mm | |

| Final Length between the 3 punch mark in mm | |

| Final Diameter in mm | |

| Original c/s area(A0)in mm2 | |

| Final area of c/s at neck in mm2 | |

| Least Count(LC) in mm | 0.01 |

| Gauge Length of the extensometer in mm | 120 |

| Yield Stress(N/mm2) | |

|---|---|

| Tensile Strength(N/mm2) | |

| Modulus of Elasticity(GPa) | |

| Percentage Elongation(%) | |

| Percentage reduction in area(%) |

| Result | Actual Value | Entered Value | Percentage Error |

|---|---|---|---|

| Yield Stress(N/mm2) | |||

| Tensile Strength(N/mm2) | |||

| Modulus of Elasticity(GPa) | |||

| Percentage Elongation(%) | |||

| Percentage reduction in area(%) |