TENSILE TEST ON CAST IRON

Objective

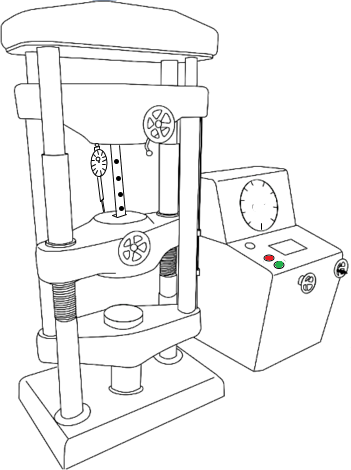

To study the mechanical properties of cast iron specimen under tension load.

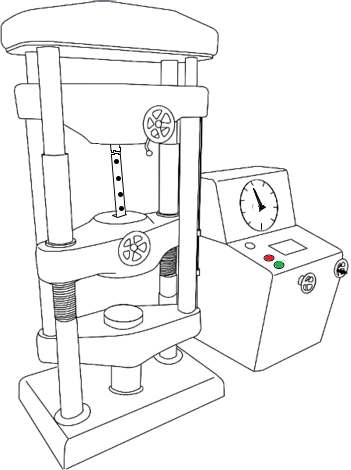

Apparatus used:

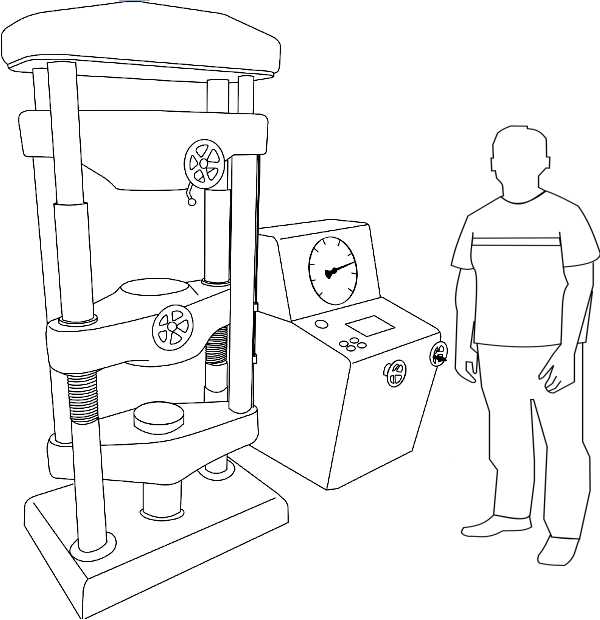

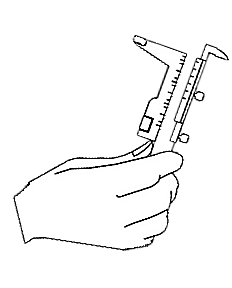

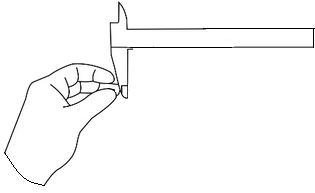

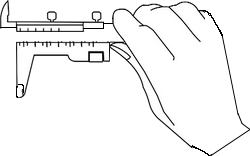

Universal Testing Machine, Dial Indicators, Extensometer, Scale & Vernier calipers.

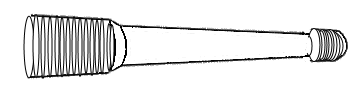

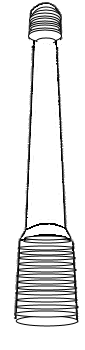

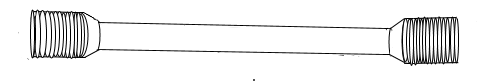

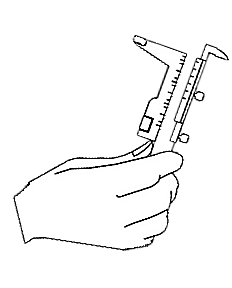

Measure the Initial Diameter of the tension test sample in two perpendicular directions using vernier caliper and calculate the initial area.

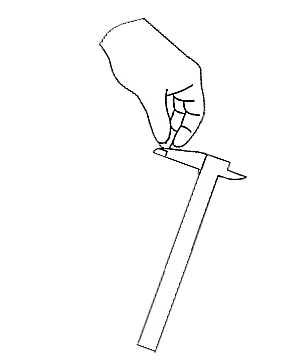

Measure the Length of the specimen between the grips using a scale.

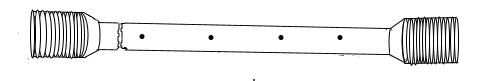

Punch marks are made at a distance of 2.5d.

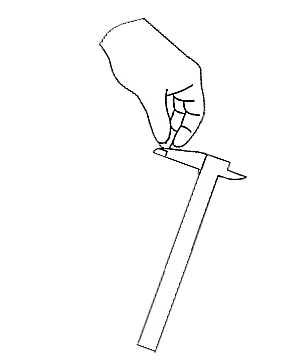

Specimen is kept in its position.Readings on dial gauge indicator are adujusted to zero.

Experiment is conducted. Load, extensometer readings are read at regular intervals of load upto the yield point. Ivory scale readings are noted till the specimen failure.

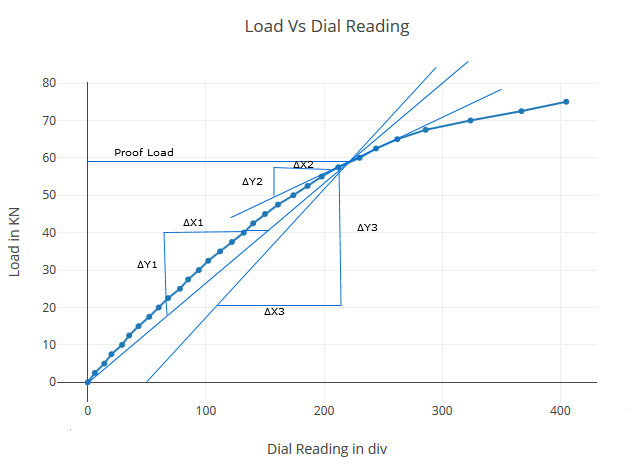

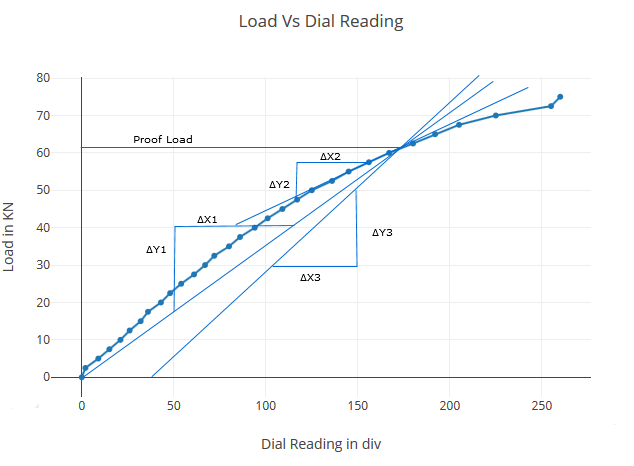

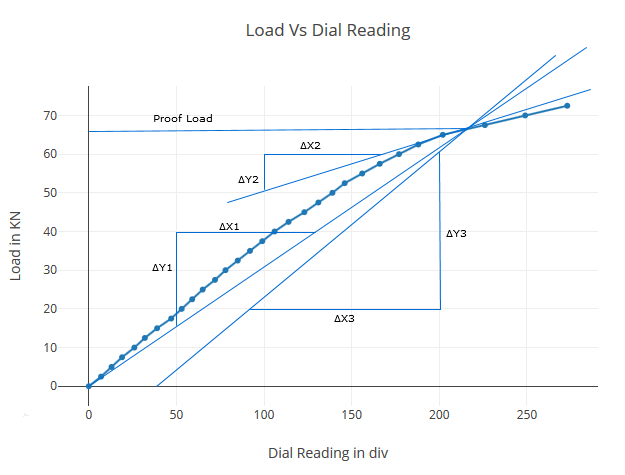

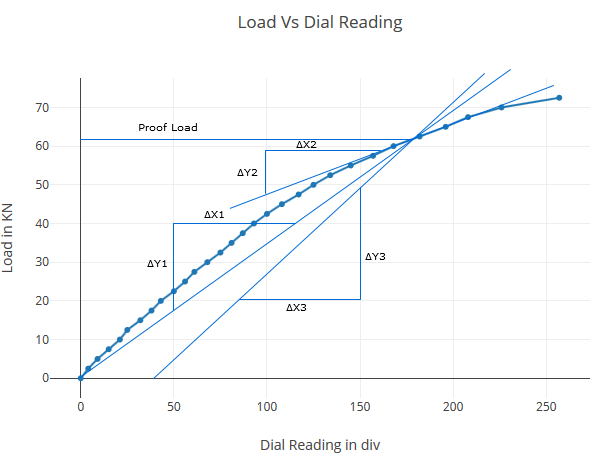

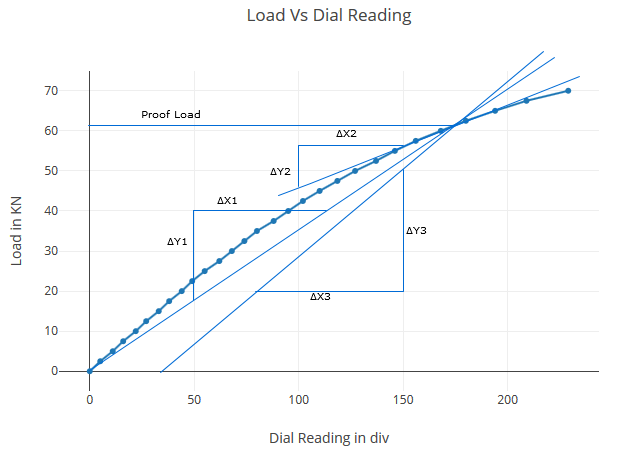

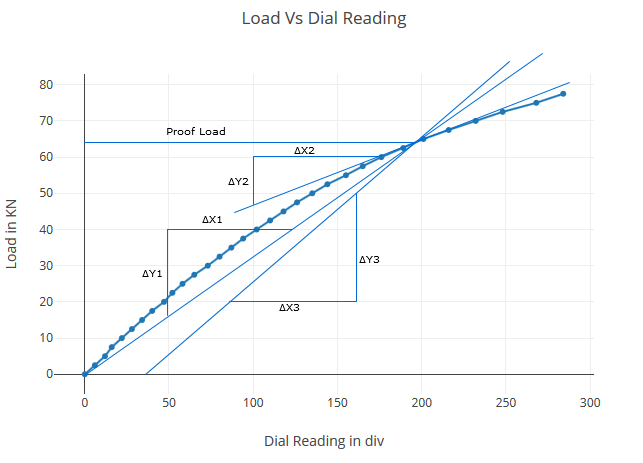

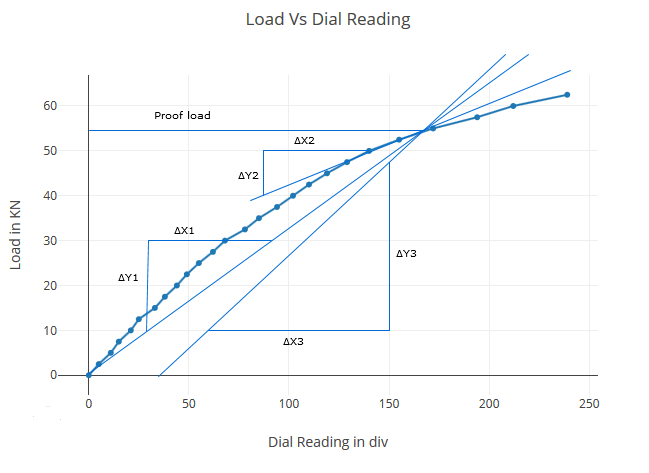

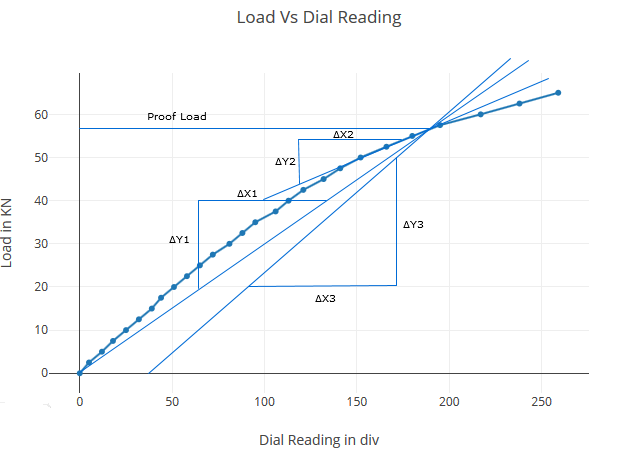

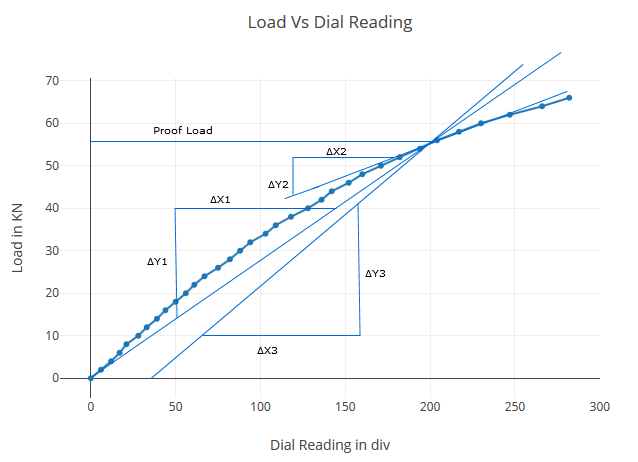

Graph.

Join two pieces of the test sample and measure the diameter at the neck of the specimen.

Measure the final length between three punch marks.

Observations and Calculations.

| Initial diameter in mm | |

|---|---|

| Length of the specimen between the grips in mm | |

| Original c/s area(A0) in mm2 | |

| Slope1 in kN/div | |

| Slope2 in kN/div | |

| Slope3 in kN/div | |

| Least Count(LC) in mm | 0.01 |

| Proof Stress(N/mm2) | |

|---|---|

| Tensile Strength(N/mm2) | |

| Secant Modulus(GPa) | |

| Tangent Modulus(GPa) | |

| Modulus of Elasticity(GPa) |

| Result | Actual Value | Entered Value | Percentage Error |

|---|---|---|---|

| Proof Stress(N/mm2) | |||

| Tensile Strength(N/mm2) | |||

| Secant Modulus(GPa) | |||

| Tangent Modulus(GPa) | |||

| Modulus of Elasticity(GPa) |