Virtual Labs

IIT Kharagpur

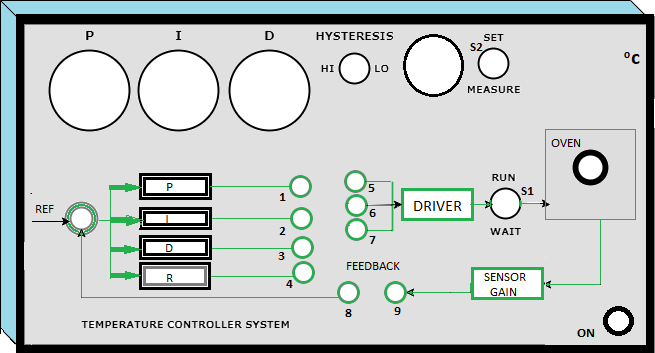

Simulation

Virtual Labs

IIT Kharagpur

Simulation

| Sl No. | Time(sec) | Temperature(℃) |

|---|

Stop Watch

00:00