Slump Test

Objective

To determine the workability of concrete mix.

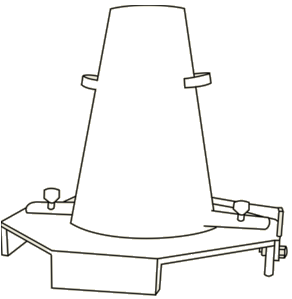

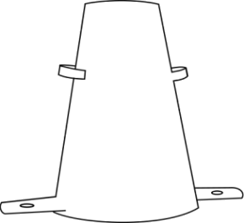

Apparatus used:

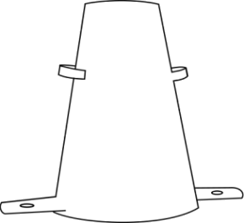

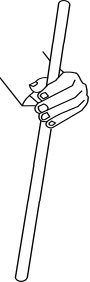

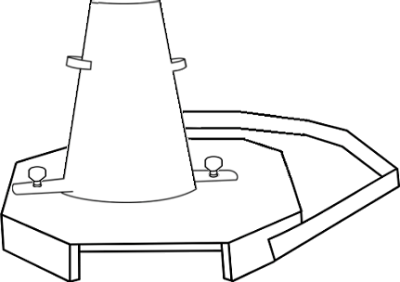

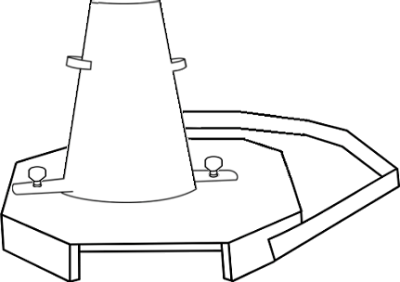

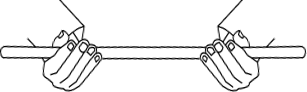

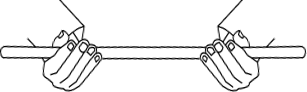

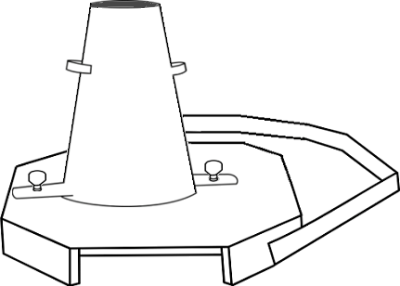

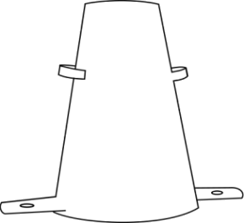

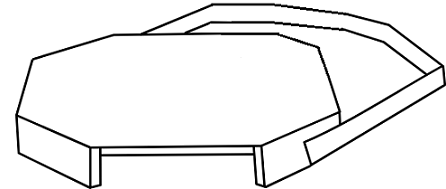

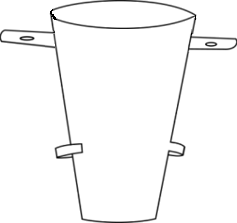

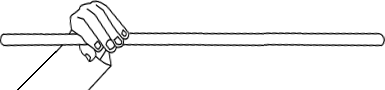

Slump cone, Tamping rod, Trowel, Measuring jar, Weighing scale, Measuring scale, Tray etc.

Description

Slump Test:It measures the consistency and workability of fresh concrete before it sets.

Workabilty of concrete:Workabilty is the relative ease with which concrete can be mixed transported, moulded and compacted.

Consistency of concrete:It is the amount of water or wetness present in the concrete.

Description

Slump Test:It measures the consistency and workability of fresh concrete before it sets.

Workabilty of concrete:Workabilty is the relative ease with which concrete can be mixed transported, moulded and compacted.

Consistency of concrete:It is the amount of water or wetness present in the concrete.

Find the volume of the cone from its dimensions ie, by measuring its height and diameter.

Volume of slump cone(frustrum) =

1⁄3 πR2H - 1⁄3 πr2h

H = 60cm

R = 10cm

h = 30cm

r = 5cm

Volume of slump cone =

x 10-3m3

✔

✘

Measure required quantity of water, coarse, fine aggregate and cement based on mix design.

Mix proportion is = 1 : 2.7 : 4.2

Water Cement ratio assumed is = 0.43

Cement content = Cement⁄Cement + C. A. + F. A.(Density × Volume × 1.52)Cement content =

Cement content = 1.6kg

✔

✘

Quantity of fine aggregate = F. A.⁄Cement + C. A. + F. A.(Density × Volume × 1.52)Quantity of fine aggregate =

Quantity of fine aggregate = 4.3kg

✔

✘

Quantity of coarse aggregate = C. A.⁄Cement + C. A. + F. A.(Density × Volume × 1.52)Quantity of coarse aggregate =

Quantity of coarse aggregate = 6.7kg

✔

✘

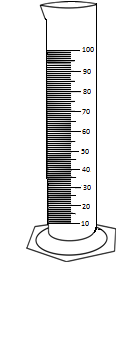

Water content = 0.43 x Cement content

Water content = 0.43 x 1.6 = 0.67Liter

52% increase in concrete=1.52

C. A. : Coarse Aggregate

F. A. : Fine Aggregate

0.000 g

g

Quantity of cement = 1.6kg

Quantity of fine aggregate = 4.3kg

Quantity of coarse aggregate = 6.7kg

Volume of water = 0.67 l

1.6kg Cement

4.3kg Fine aggregate

6.7kg Coarse aggregate

Dry mix the materials properly.

Add measured quantity of water, mix it thoroughly and uniformly.

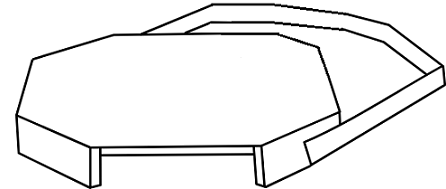

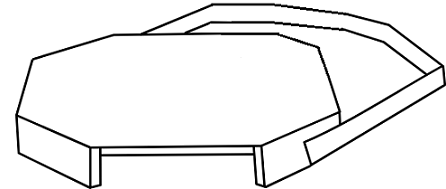

Place the cleaned slump cone on a horizontal slump base.

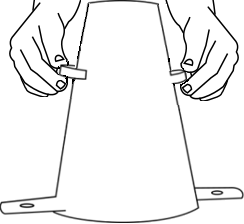

Fill the mould in four layers, each layer is tamped 25 times by a tamping rod.

Remove extra concrete with the trowel and tamping rod.

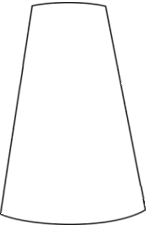

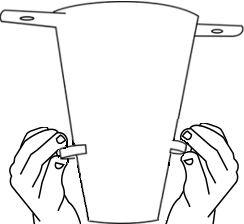

Remove the mould from the concrete immediately by raising it slowly in vertical direction.

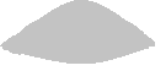

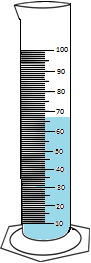

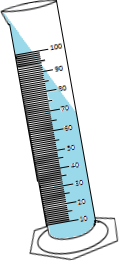

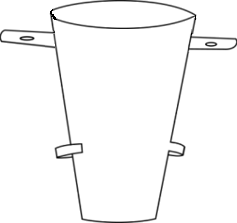

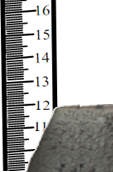

Note down the slump by keeping slump cone mould as reference.

Slump value = 30 - 12 = 18cm

Observation

| Water cement ratio assumed | 0.43 |

| Mix proportion | 1 : 2.7 : 4.2 |

| Quantity of cement | 1.6kg |

| Quantity of fine aggregate | 4.3kg |

| Quantity of coarse aggregate | 6.7kg |

| Volume of water | 0.67l |

| Slump value | 18cm |

Inference:

Degree of workability is high.

Trial =