DUCTILITY TEST ON BITUMEN

Objective:

To determine the ductility value of asphaltic bitumen.

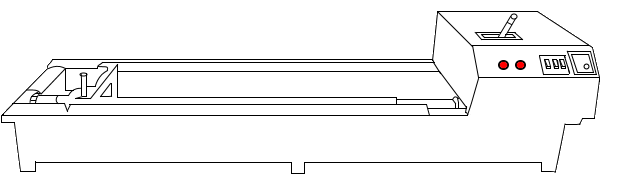

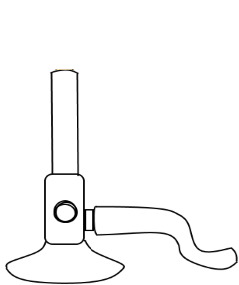

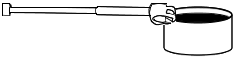

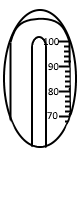

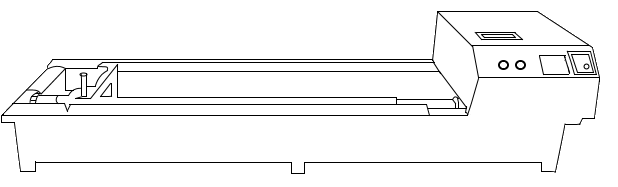

Apparatus used:

Briquette Mould, Ductility Setup, Water Bath, Bunsen Burner.

Description Ductility Test: is the property of bitumen that permits it to undergo great deformation or elongation.

The bituminous material is heated to a pouring temperature and is poured to the briquette mould on a brass plate.

In order to prevent the material under test from sticking, coat the surface of the plate and interior surface of the sides of the mould with mercury or by a mixture of equal parts of glycerin and dextrin.

In order to prevent the material under test from sticking, coat the surface of the plate and interior surface of the sides of the mould with mercury or by a mixture of equal parts of glycerin and dextrin.

Grade of bitumen sample used here is: S90

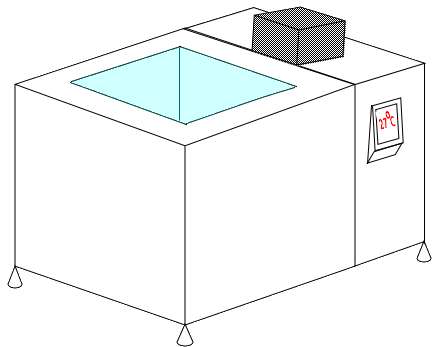

Place the sample in water bath maintained at a temperature of 27°C for half an hour.

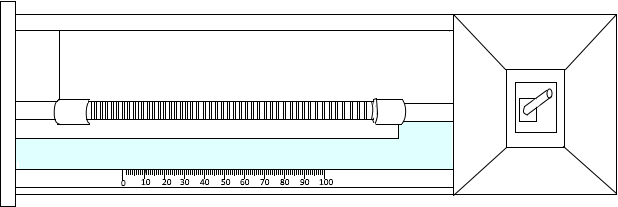

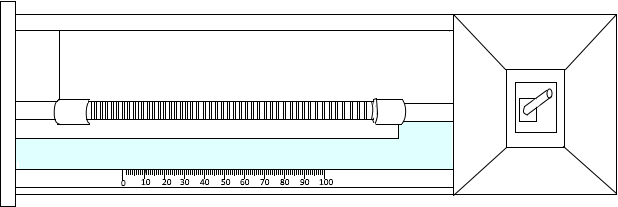

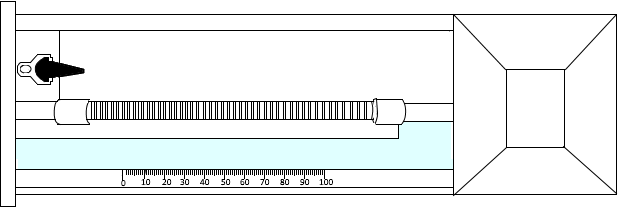

Adjust the pointer of the machine to read zero.

Pointer is not set to zero

Place the mould on the machine and hook the clips carefully on the machine without causing any initial strain.

Mould with bitumen sample is taken out from waterbath.

Mould with bitumen sample is taken out from waterbath.

Start the machine and apply the tension load at a speed of 50 mm per minute.

| Trial No | Initial Reading (cm) | Final Reading (cm) | Ductility Value (cm) |

Observation and Results.

| Trial No | Initial Reading (cm) | Final Reading (cm) | Ductility Value (cm) |

The minimum ductility value for S90 grade of bitumen is 75cm, hence bitumen with this ductility value is suitable for pavement construction.

Trial =

Both ends of the pipe must be trimmed to ensure parallel faces.

Both ends of the pipe must be trimmed to ensure parallel faces.