COMPRESSION TEST ON CAST IRON

Objective

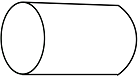

To study the mechanical properties of cast iron specimen under compression.

Apparatus used:

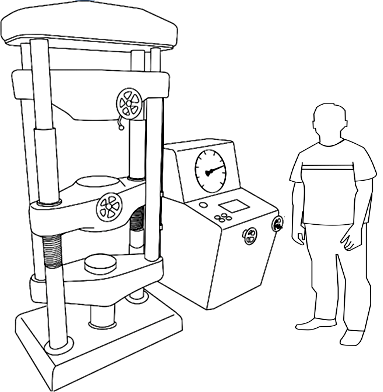

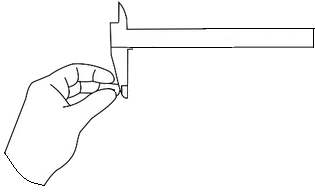

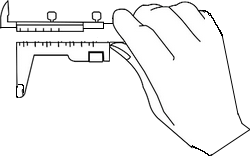

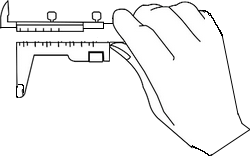

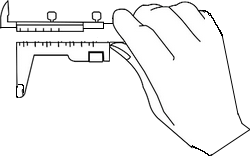

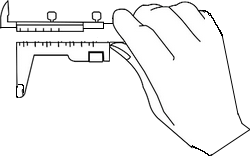

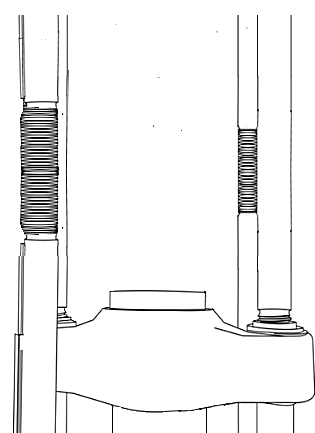

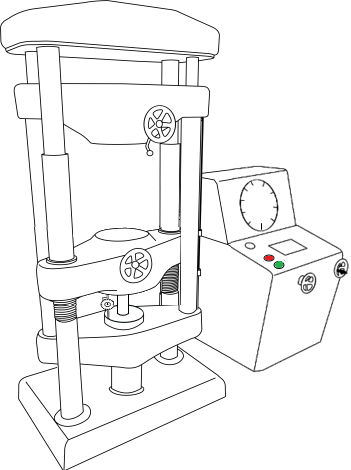

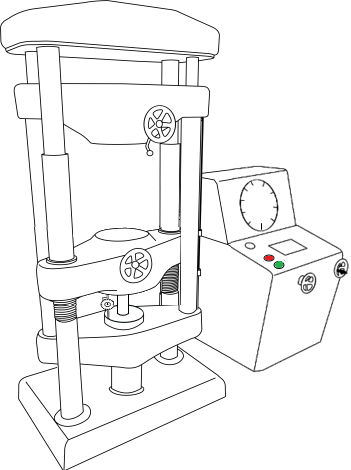

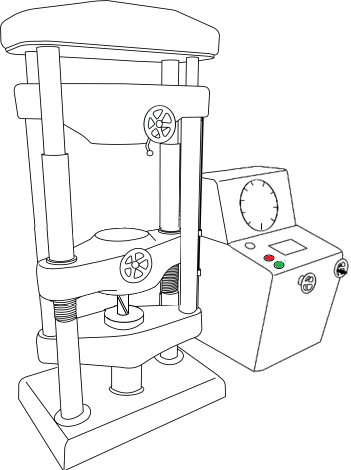

Universal Testing Machine,Dial Indicators,Scale & Vernier calipers.

STEP

1

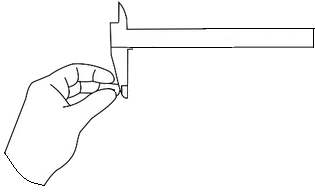

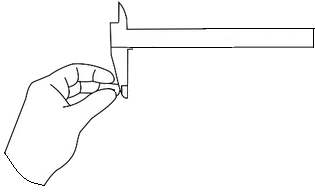

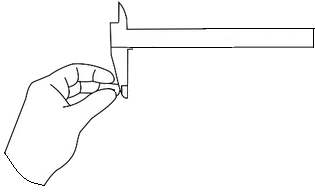

Measure the Diameter of the test sample using vernier caliper and calculate the Moment of Inertia.

| Initial Diameter in two perpendicular directions | Average initial diameter di (mm) | |

| dix(mm) | diy(mm) | |

| d1x= | d1y= | |

STEP

2

Measure the length of the specimen.

STEP 3

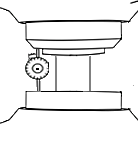

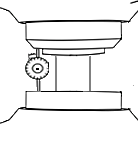

Sample is placed in the UTM.

STEP 4

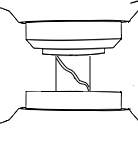

Start the loading process, note down the deflections using dial gauge for corresponding load intervals.The shape of fracture for brittle material is studied.

STEP 5

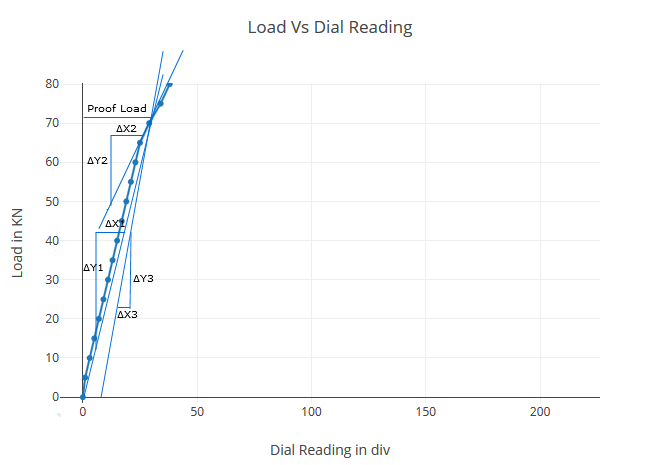

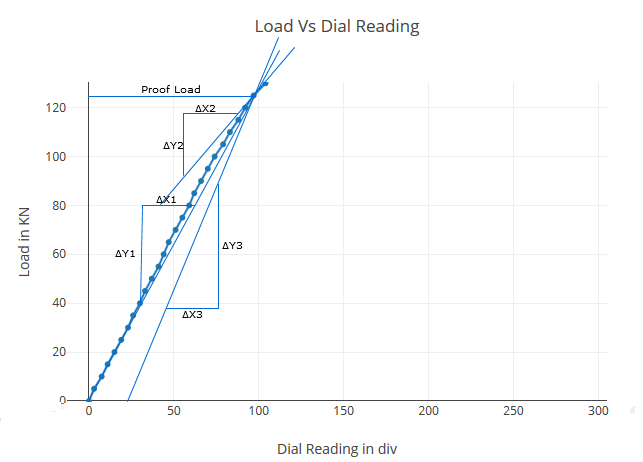

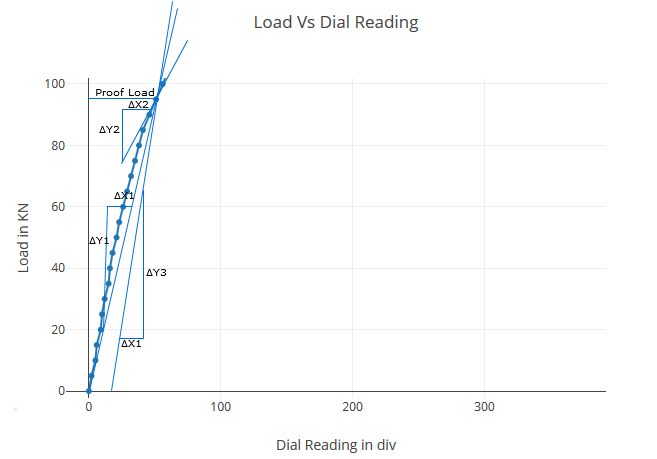

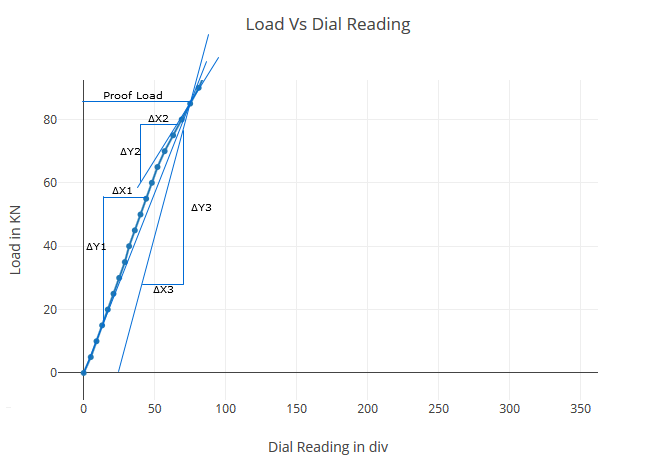

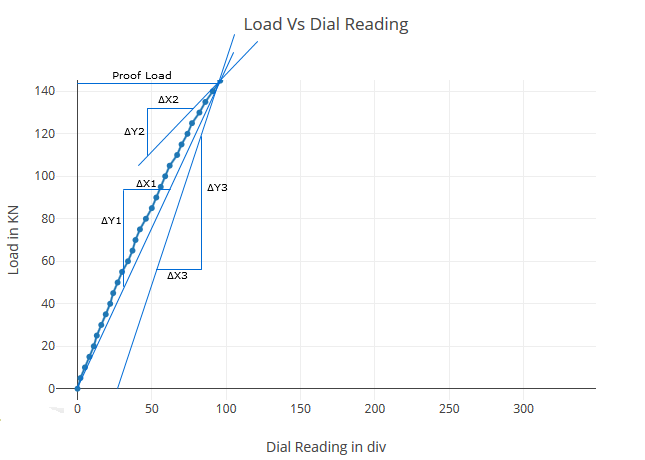

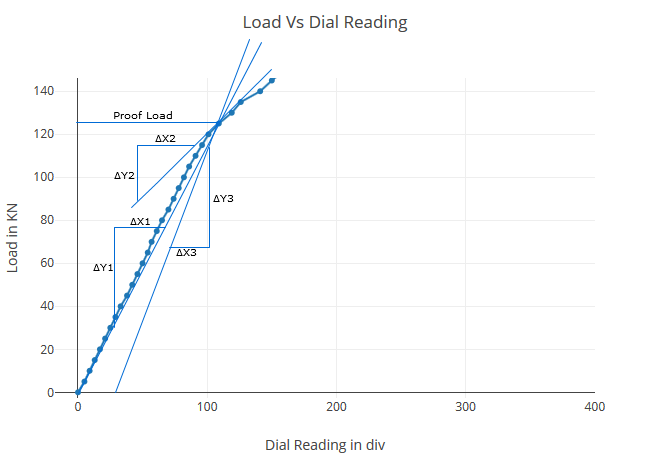

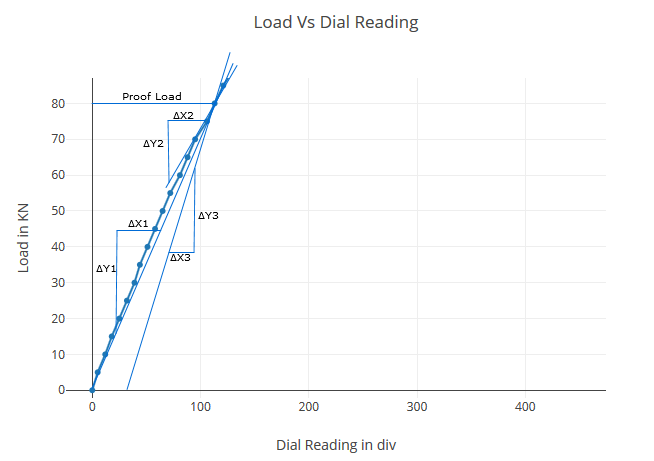

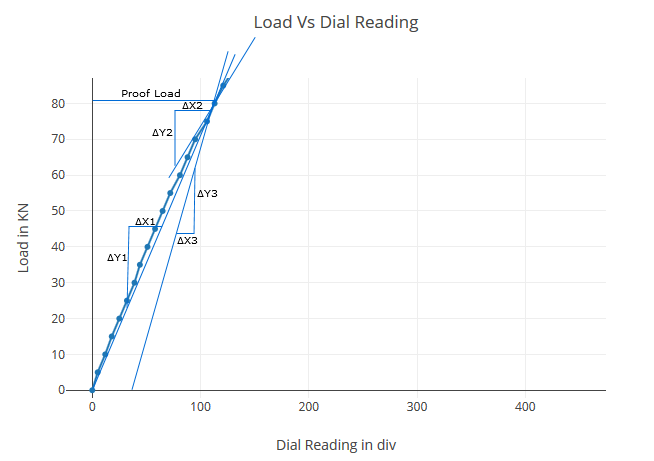

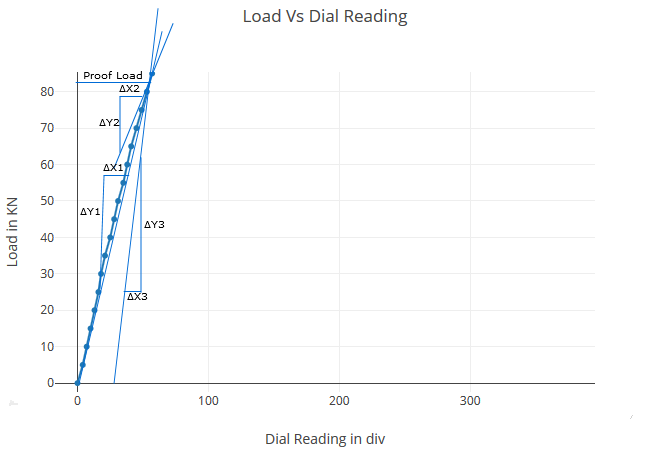

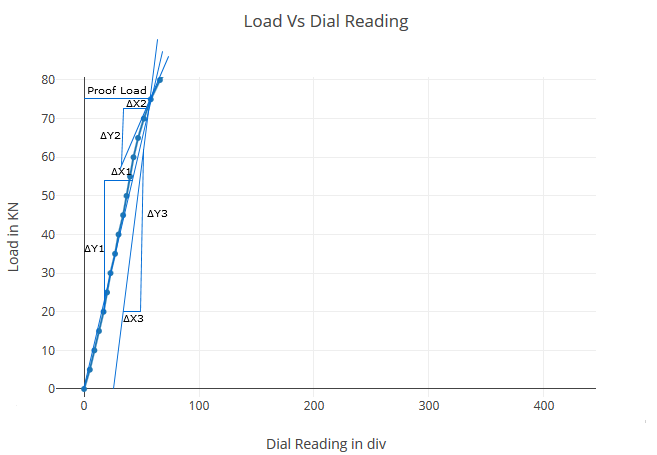

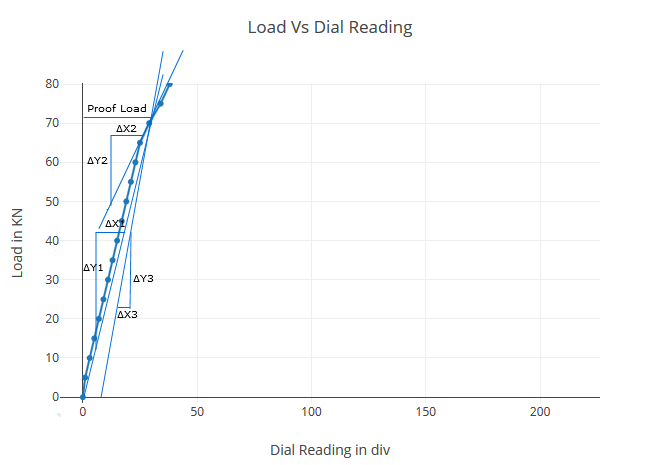

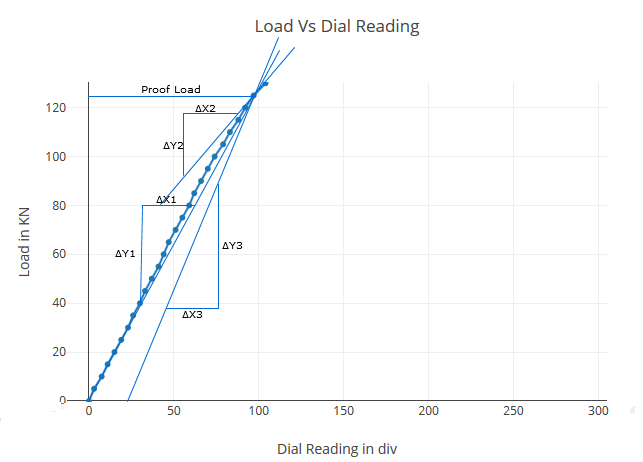

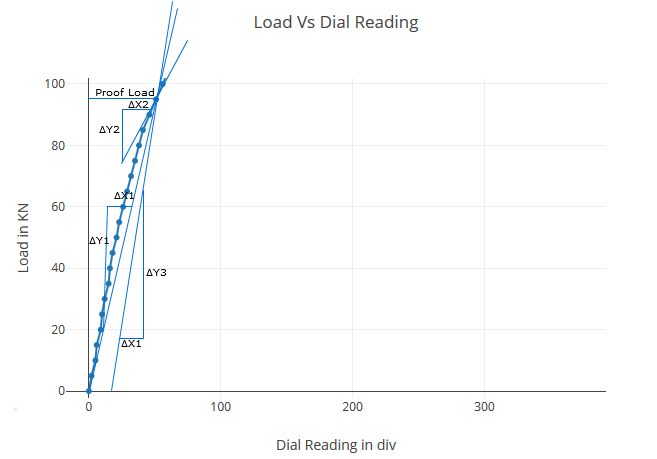

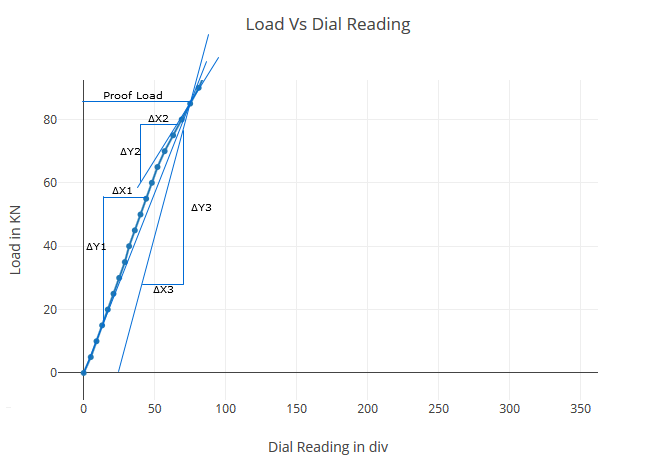

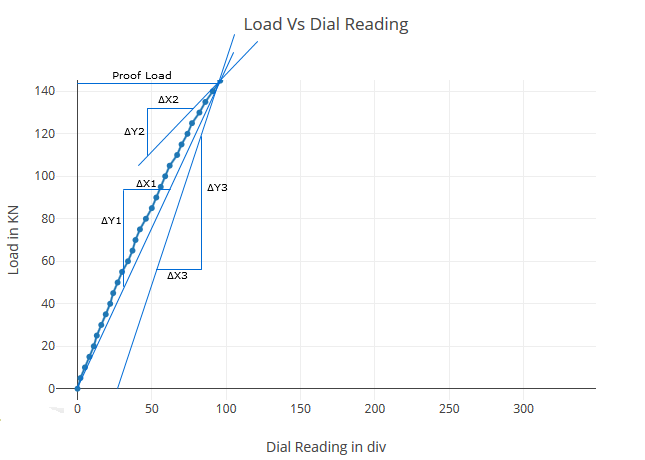

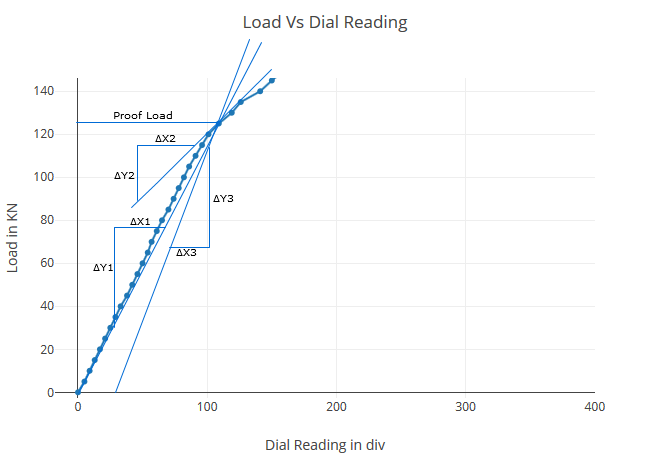

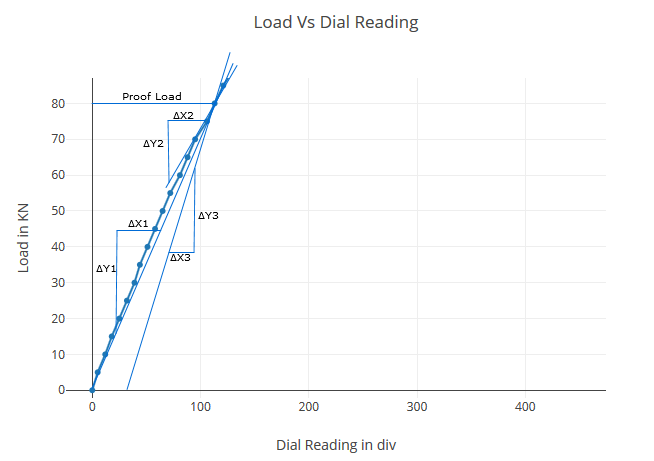

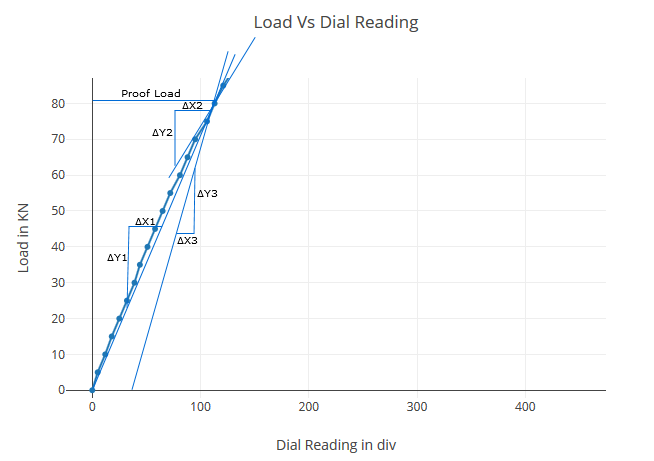

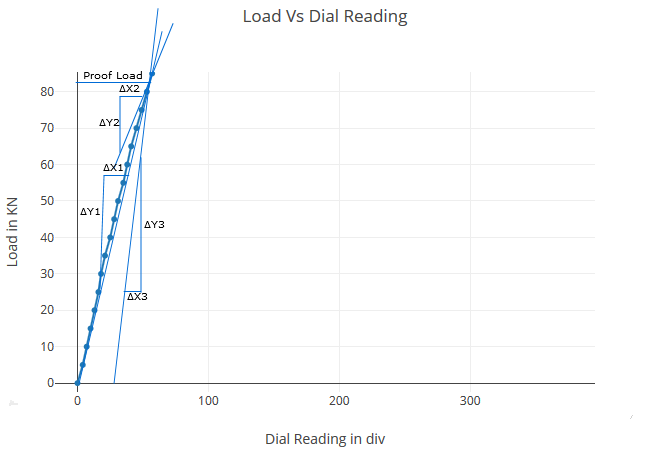

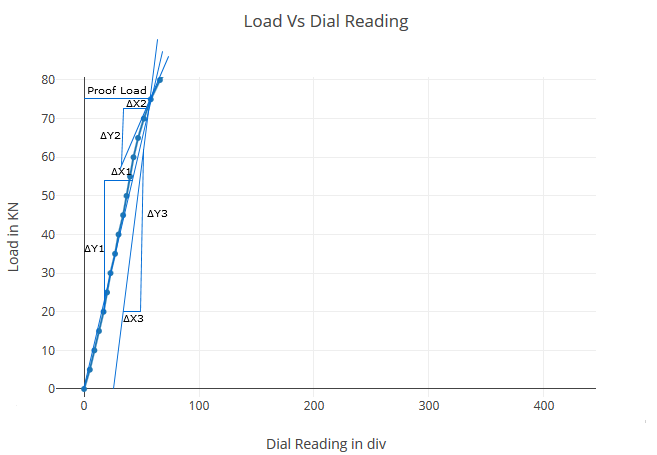

Graph.

STEP 6

Observations and Calculations.

| Initial diameter in mm | |

|---|---|

| Length of the specimen between the grips in mm | |

| Original c/s area(A0)in mm2 | |

| Slope1 in kN/div | |

| Slope2 in kN/div | |

| Slope3 in kN/div | |

| Least Count(LC) in mm | 0.01 |

| Proof Stress(N/mm2) | |

|---|---|

| Compressive Strength(N/mm2) | |

| Secant Modulus(GPa) | |

| Tangent Modulus(GPa) | |

| Modulus of Elasticity(GPa) |

| Result | Actual Value | Entered Value | Percentage Error | Proof Stress(N/mm2) | Compressive Strength(N/mm2) | Secant Modulus(GPa) | Tangent Modulus(GPa) | Modulus of Elasticity(GPa) |

|---|

© 2016 - 2020 SOLVE - The Virtual Lab @ NITK Surathkal, Department of Water Resources & Ocean Engineering