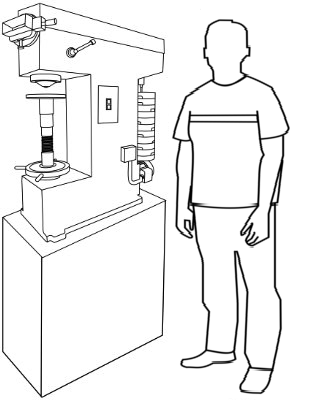

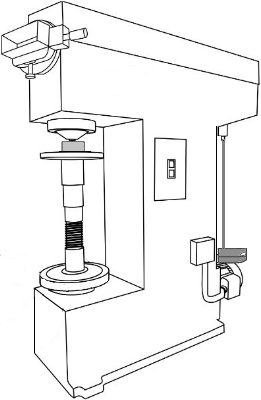

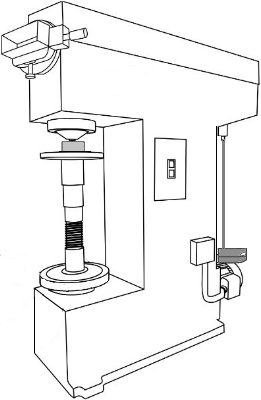

BRINELL HARDNESS TEST

Objective :

To determine the indentation hardness of Mild Steel, Cast Iron, Brass and Alluminium etc. using Brinell hardness testing machine.

Apparatus used :

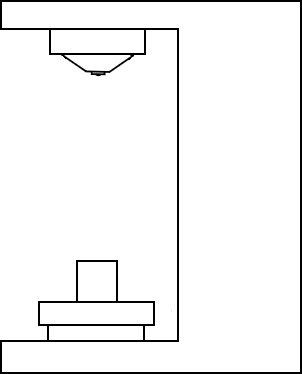

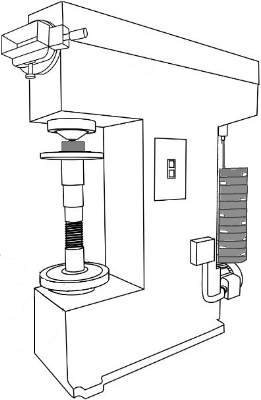

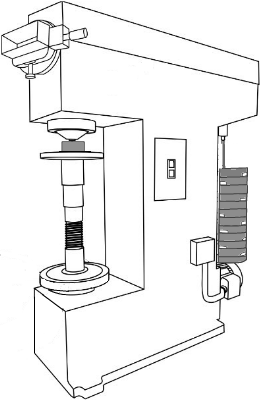

Brinell hardness testing machine

Diameter of the indentor D = 10mm. Select the load P based on the type of material selected (Mild Steel, Cast Iron, Brass, Alluminium).

Select material :

Selected material :

Cast Iron Load : 3000Kg

Mild Steel Load : 3000Kg

Brass Load : 1000Kg

Aluminium Load : 500Kg

Cast Iron

Mild Steel

Brass

Aluminium

Mild Steel

Brass

Aluminium

| Material | Load ‘P’ (kg), diameter ‘D’ (mm) (Diameter of the indentor D=10mm) |

| Cast Iron & Mild Steel | P/D2 = 30, P = 3000Kg |

| Brass, copper & bronze | P/D2 = 10, P = 1000Kg |

| Aluminum, Magnesium & Zinc | P/D2 = 5, P = 500Kg |

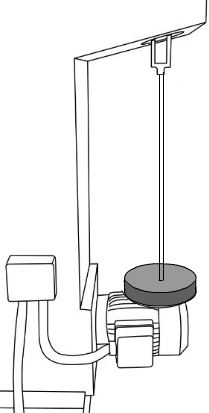

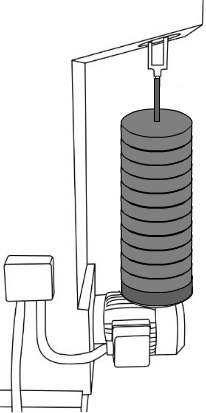

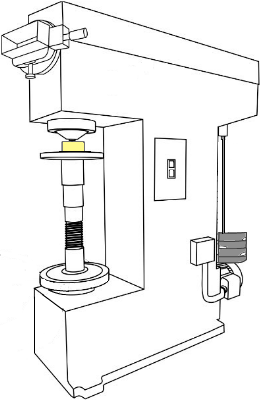

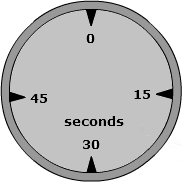

( Each weight is equivalent to 250Kg, supporting

hanging rod and base plate is 250Kg )

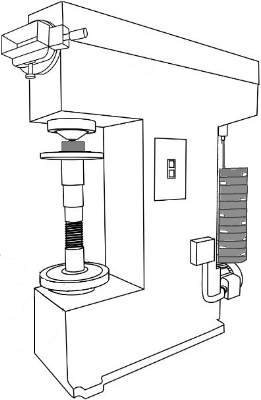

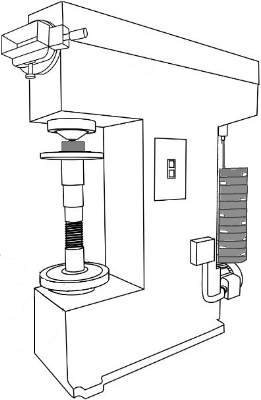

The specimen is placed on the supporting table, then the hand wheel below the table is turned in clockwise direction untill the gap between the surface of the specimen and the indentor is 5mm.

Specimen is in position

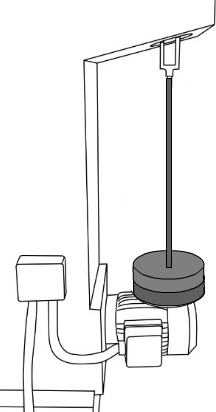

Unload Load

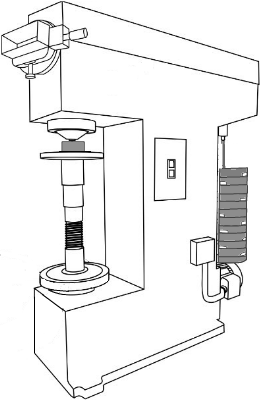

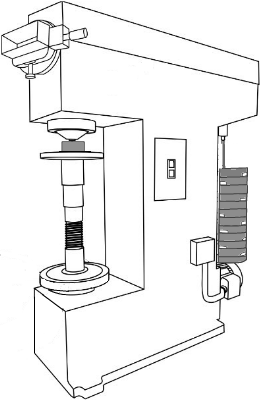

The motor is switched ON. The hand lever is pulled into load position. The load is applied for a period of 10 to 15 seconds.

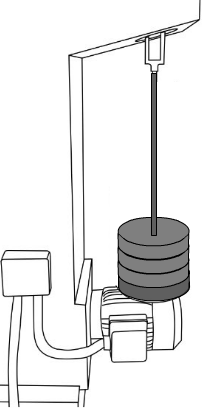

Unload Load

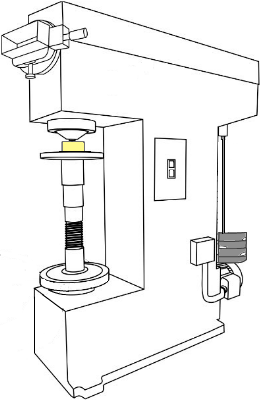

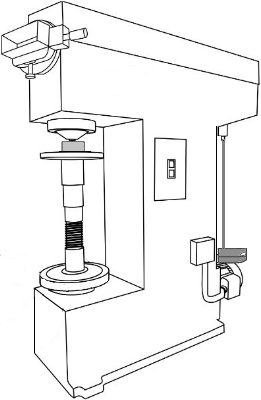

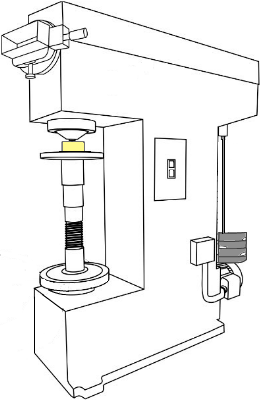

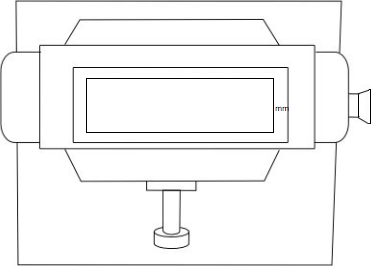

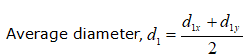

The hand lever is pulled back into unload position. The diameter of the impression is measured through a microscope attached to the apparatus.

Measured Diameter :

sq=

Move the mouse cursor on

the knob to measure

Impression diameter

Unload Load

Observations:

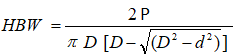

Calculate the Brinell Hardness Number (HBW)

[HBW (H from hardness, B from brinell and W from the material of the indenter, tungsten (wolfram) carbide)]

| Material | Diameter of indenter D ( mm ) |

Load P ( kg ) | P/D2 | Diameter of indentation ( mm ) | Average diameter di ( mm ) |

d/D | HBW (kg/mm2) |

|

| dix ( mm ) |

diy ( mm ) |

|||||||

Actual HBW =

Entered HBW =

| Trial | Material | Diameter of indenter D ( mm ) |

Load P ( kg ) |

Average diameter di ( mm ) |

HBW ( kg/mm2 ) |

Average HBW ( kg/mm2 ) |

| 1 | ||||||

| 2 |

Trial =