Virtual Labs

IIT Kharagpur

Simulation

Virtual Labs

IIT Kharagpur

Simulation

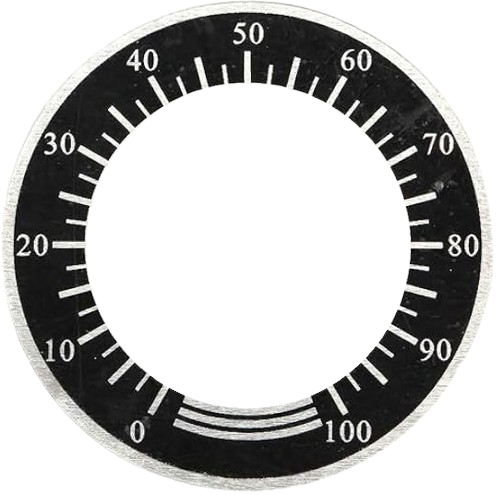

Speed (rpm) :

Speed (rpm) :

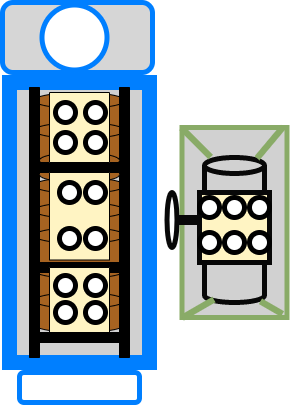

Control phase voltage (V) :

Control phase voltage (V) :

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

| Ec = V | ||||

|---|---|---|---|---|

| Sl No. | Weight(g) | Speed(rpm) | Speed(rad/s) | Torque |

| Ec = V | ||||

|---|---|---|---|---|

| Sl No. | Weight(g) | Speed(rpm) | Speed(rad/s) | Torque |

| Ec = V | ||||

|---|---|---|---|---|

| Sl No. | Weight(g) | Speed(rpm) | Speed(rad/s) | Torque |